- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 23, 2024 07:56 Back to list

foundry iron

The Art and Science of Foundry Iron

Foundry iron, a term synonymous with cast iron, represents a fascinating intersection between craftsmanship and engineering. Its history stretches back thousands of years, where it has played a pivotal role in the development of various industries and societies. As we explore the characteristics, production processes, and applications of foundry iron, it becomes clear why this material remains relevant in modern times.

Characteristics of Foundry Iron

Foundry iron is primarily composed of iron, carbon, and silicon, with varying percentages of these elements resulting in different types of cast iron. The most notable types include gray iron, ductile iron, and white iron, each possessing unique properties that make them suitable for various applications. For instance, gray iron is known for its excellent machinability and vibration dampening qualities, while ductile iron exhibits higher tensile strength and ductility, making it ideal for more demanding applications.

The carbon content in foundry iron is typically around 3% to 4%, contributing to its solidified structure and unique properties. The microstructure of cast iron, characterized by the presence of graphite flakes, influences its strength, hardness, and wear resistance. The casting process can further enhance these properties, giving manufacturers flexibility in designing components for specific uses.

The Foundry Process

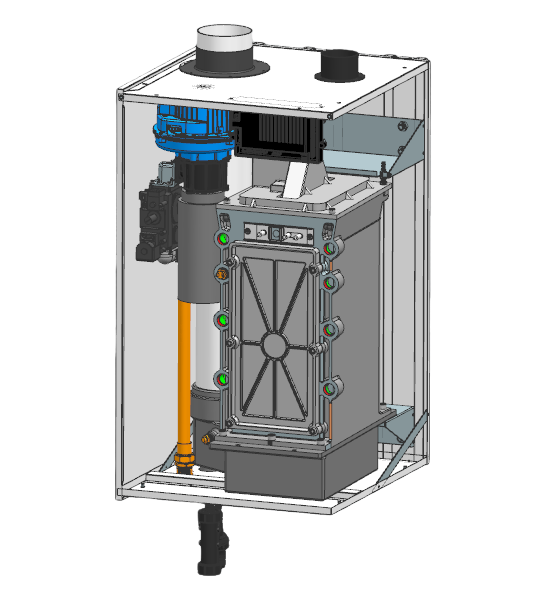

The production of foundry iron involves a complex process that includes melting, casting, and cooling

. The first step is the melting of iron and the alloying elements in a furnace, which can be an electric arc furnace, induction furnace, or cupola furnace. Temperature control is crucial during this phase to maintain the desired properties.After melting, the molten iron is poured into a mold to create the desired shape. Molds can be made from various materials, including sand, metal, or plaster, each offering different benefits. The choice of mold material can significantly influence the surface finish and dimensional accuracy of the final product.

foundry iron

Once the iron cools and solidifies, it undergoes several finishing processes. These can include machining, heat treatment, and surface finishing to improve quality and performance. The entire foundry process is not just about creating a product but is also a testament to the skill and expertise of the foundry workers who oversee these operations.

Applications of Foundry Iron

The versatility of foundry iron makes it a favored material in many industries. It is extensively used in the automotive sector for manufacturing engine blocks, cylinder heads, and various other components due to its excellent wear resistance and machinability. Additionally, its use in construction is notable, particularly in the production of pipes, manhole covers, and structural elements, benefiting from its strength and durability.

In the context of household items, cast iron cookware has seen a resurgence in popularity. Its ability to retain and evenly distribute heat makes it ideal for cooking, and with proper care, cast iron cookware can last for generations. Moreover, the aesthetic appeal of cast iron, particularly in vintage designs, continues to attract consumers.

Beyond traditional applications, foundry iron is making strides in emerging technologies as well. The rise of smart manufacturing and the integration of industry 4.0 are leading to innovative casting techniques and applications of cast iron in machinery and infrastructure, showcasing its adaptability in a rapidly changing world.

Conclusion

In conclusion, foundry iron stands as a testament to human ingenuity and resilience. Its properties, versatility, and adaptability have cemented its place across various sectors, from traditional manufacturing to modern technology. As we look to the future, the ongoing evolution of casting techniques promises to unlock even more potential from this remarkable material, ensuring that foundry iron remains an integral part of our industrial landscape. Whether in intricate machinery or everyday cooking utensils, foundry iron will undoubtedly continue to shape our world.

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025

-

High-Quality Cast Iron Water Main Pipe for Durable Infrastructure

NewsJul.30,2025