- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 23, 2024 07:53 Back to list

stamp concrete pipe mold bottom ring factory

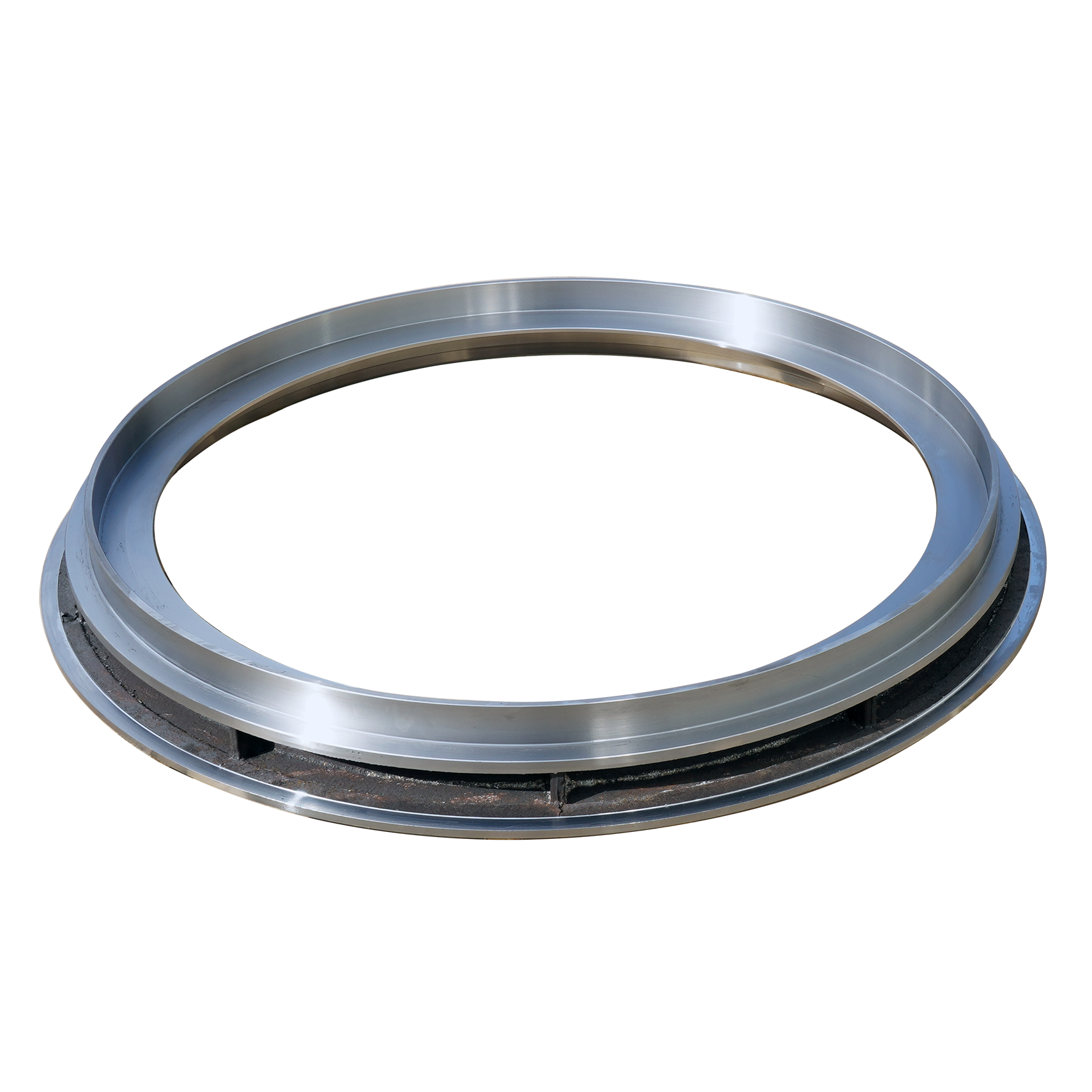

Exploring the World of Stamp Concrete Pipe Mold Bottom Ring Manufacturing

In the modern construction and infrastructure landscape, the production of concrete pipes is an essential component. These pipes are critical for various applications, including drainage, sewage systems, and culverts. At the heart of this manufacturing process lies the technology of concrete pipe molds, particularly the bottom rings used in their formation. Understanding how these molds are created, especially from a factory perspective, provides insight into a vital yet often overlooked industry segment.

Stamp concrete pipe mold bottom rings are specifically designed to ensure consistent, high-quality production of concrete pipes. The molding process utilizes advanced techniques to shape and form the bottom rings, ensuring that they meet strict engineering standards and specifications. Factories specializing in this niche are equipped with the latest technology and skilled labor to produce durable and precise mold components.

One of the key advantages of using stamped molds in the production of bottom rings is the efficiency they bring to the manufacturing process. Stamped molds allow for a higher degree of precision and uniformity, which translates into lower material waste and enhanced product performance. This is crucial in minimizing production costs while maximizing quality—a balance that every manufacturer strives to achieve.

stamp concrete pipe mold bottom ring factory

Moreover, the materials used in the fabrication of these molds are of paramount importance. High-grade steel and alloy materials are often selected to withstand the immense pressures and wear associated with concrete forming processes. Factories typically employ rigorous testing protocols to ensure that their molds can endure the demanding conditions of concrete pouring and curing.

Environmental sustainability is another factor influencing the manufacturing of concrete pipe mold bottom rings. Many factories are adopting eco-friendly practices by incorporating recycled materials and reducing emissions during the production process. This shift not only benefits the environment but also aligns with the growing consumer demand for sustainable construction materials.

Furthermore, the global construction market is experiencing a surge in demand for concrete pipes, driven by infrastructure development and urbanization. Factories that specialize in producing stamp concrete pipe mold bottom rings are positioned to meet this demand by optimizing their production capabilities and enhancing their product offerings.

In conclusion, the manufacturing of stamp concrete pipe mold bottom rings is a critical part of the concrete pipe industry. As construction needs evolve, so too does the technology and methods behind the production of these essential components. By focusing on quality, efficiency, and sustainability, these factories play a pivotal role in supporting infrastructure development worldwide.

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025