Feb . 14, 2025 13:47 Back to list

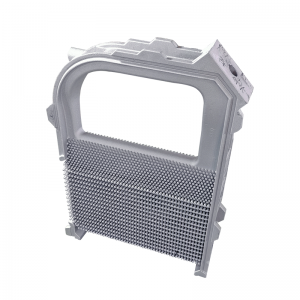

marine shell and tube heat exchanger

Marine shell and tube heat exchangers play a pivotal role in marine engineering, particularly in applications that demand efficient thermal energy transfer. With decades of advancements, these heat exchangers are now designed to meet the increasing demands for performance and environmental sustainability.

Trustworthiness is central to marine equipment, where failure can have dire consequences. Manufacturers provide extensive documentation, including complete lifecycle analyses and performance guarantees, which are indispensable for marine operators. Regular maintenance and inspections form an integral part of the lifecycle management, where predictive maintenance techniques are increasingly adopted using AI and IoT technologies. These advanced methodologies enable operators to foresee potential failures and perform necessary interventions before significant issues arise. The sustainable design of marine shell and tube heat exchangers is also gaining prominence, driven by global directives to lower emissions in maritime operations. Innovations such as enhanced surface geometries and nano-coatings significantly improve heat transfer coefficients and reduce fouling, leading to higher efficiency and lower energy consumption. These eco-friendly enhancements align with the maritime industry’s goal towards sustainability without sacrificing performance. In practical marine applications, these heat exchangers are indispensable in systems such as engine cooling, waste heat recovery, and HVAC systems on maritime vessels. Their efficiency directly impacts fuel consumption, CO2 emissions, and overall vessel performance. By optimizing the thermal processes, these systems contribute to more energy-efficient operations, which is crucial in today’s environmentally-conscious and cost-sensitive marine sector. In summary, the efficacy of marine shell and tube heat exchangers lies in their robust design, material resilience, and precise engineering. Extensive expertise ensures these systems adapt well to the rigorous demands of marine environments, while authoritative standards guarantee their quality and performance. Trust is built through detailed maintenance strategies and sustainable practices, making marine shell and tube heat exchangers a critical component in modern marine operations for improved energy efficiency and reduced environmental impact.

Trustworthiness is central to marine equipment, where failure can have dire consequences. Manufacturers provide extensive documentation, including complete lifecycle analyses and performance guarantees, which are indispensable for marine operators. Regular maintenance and inspections form an integral part of the lifecycle management, where predictive maintenance techniques are increasingly adopted using AI and IoT technologies. These advanced methodologies enable operators to foresee potential failures and perform necessary interventions before significant issues arise. The sustainable design of marine shell and tube heat exchangers is also gaining prominence, driven by global directives to lower emissions in maritime operations. Innovations such as enhanced surface geometries and nano-coatings significantly improve heat transfer coefficients and reduce fouling, leading to higher efficiency and lower energy consumption. These eco-friendly enhancements align with the maritime industry’s goal towards sustainability without sacrificing performance. In practical marine applications, these heat exchangers are indispensable in systems such as engine cooling, waste heat recovery, and HVAC systems on maritime vessels. Their efficiency directly impacts fuel consumption, CO2 emissions, and overall vessel performance. By optimizing the thermal processes, these systems contribute to more energy-efficient operations, which is crucial in today’s environmentally-conscious and cost-sensitive marine sector. In summary, the efficacy of marine shell and tube heat exchangers lies in their robust design, material resilience, and precise engineering. Extensive expertise ensures these systems adapt well to the rigorous demands of marine environments, while authoritative standards guarantee their quality and performance. Trust is built through detailed maintenance strategies and sustainable practices, making marine shell and tube heat exchangers a critical component in modern marine operations for improved energy efficiency and reduced environmental impact.

Share

Pervious:

Next:

Latest news

-

Durable Cast Steel Concrete Pipe Mold Bottom Rings & Base Trays

NewsAug.23,2025

-

Centrifugally Cast Iron Water Main Pipe for Reliable Mains

NewsAug.22,2025

-

Durable Centrifugally Cast Iron Water Main Pipe

NewsAug.11,2025

-

Centrifugally Cast Iron Water Main Pipes for Reliability

NewsAug.10,2025

-

High-Quality Centrifugally Cast Iron Water Main Pipes

NewsAug.09,2025

-

Durable Cast Iron Water Main Pipe & Drainage Solutions

NewsAug.08,2025