- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jan . 17, 2025 03:48 Back to list

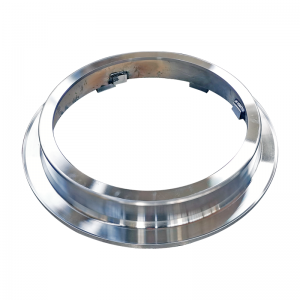

mining machinery steel casting

In the dynamic realm of industrial engineering, the importance of understanding and choosing the right machinery parts cannot be overstated. These components are the backbone of any mechanical operation, and their quality can significantly impact productivity, efficiency, and overall operational success.

The purchase of machinery parts should not be approached as a mere expense, but as a long-term investment in operational excellence. High-quality parts reduce downtime, minimize maintenance costs, and extend the life of machinery, offering a tangible return on investment. As an authority in the field, one must stress the importance of sourcing parts from trusted manufacturers who use advanced materials and engineering techniques to produce components that withstand the rigors of industrial use. Another critical aspect of expertise in machinery parts involves staying at the forefront of technological advancements. The industry is perpetually evolving, with innovations such as IoT integration into machinery parts that allow for predictive maintenance and enhanced efficiency. Being knowledgeable about these developments and understanding their practical applications can provide a significant competitive edge, ensuring machinery not only meets current demands but is also future-proofed against upcoming technological challenges. Moreover, a profound understanding of machinery part compatibility is essential. Mismatched or substandard parts can lead to significant mechanical failures, resulting in costly downtime and potential safety hazards. Here, the expertise of a seasoned mechanical engineer or a trusted supplier becomes invaluable. They can provide insights into the compatibility of parts based on specific machine models, operational conditions, and expected workloads. In conclusion, when it comes to machinery parts, expertise and trustworthiness are indispensable traits that industries cannot overlook. The far-reaching implications of part selection on operational efficiency necessitate a meticulous approach, underpinned by sound engineering principles and an authoritative knowledge base. For any company looking to maximize their machinery's potential, partnering with credible experts who demonstrate these qualities will undoubtedly lead to enhanced productivity and sustained operational success.

The purchase of machinery parts should not be approached as a mere expense, but as a long-term investment in operational excellence. High-quality parts reduce downtime, minimize maintenance costs, and extend the life of machinery, offering a tangible return on investment. As an authority in the field, one must stress the importance of sourcing parts from trusted manufacturers who use advanced materials and engineering techniques to produce components that withstand the rigors of industrial use. Another critical aspect of expertise in machinery parts involves staying at the forefront of technological advancements. The industry is perpetually evolving, with innovations such as IoT integration into machinery parts that allow for predictive maintenance and enhanced efficiency. Being knowledgeable about these developments and understanding their practical applications can provide a significant competitive edge, ensuring machinery not only meets current demands but is also future-proofed against upcoming technological challenges. Moreover, a profound understanding of machinery part compatibility is essential. Mismatched or substandard parts can lead to significant mechanical failures, resulting in costly downtime and potential safety hazards. Here, the expertise of a seasoned mechanical engineer or a trusted supplier becomes invaluable. They can provide insights into the compatibility of parts based on specific machine models, operational conditions, and expected workloads. In conclusion, when it comes to machinery parts, expertise and trustworthiness are indispensable traits that industries cannot overlook. The far-reaching implications of part selection on operational efficiency necessitate a meticulous approach, underpinned by sound engineering principles and an authoritative knowledge base. For any company looking to maximize their machinery's potential, partnering with credible experts who demonstrate these qualities will undoubtedly lead to enhanced productivity and sustained operational success.

Share

Pervious:

Latest news

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025