- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Feb . 10, 2025 23:24 Back to list

Gray Cast Iron Products Service

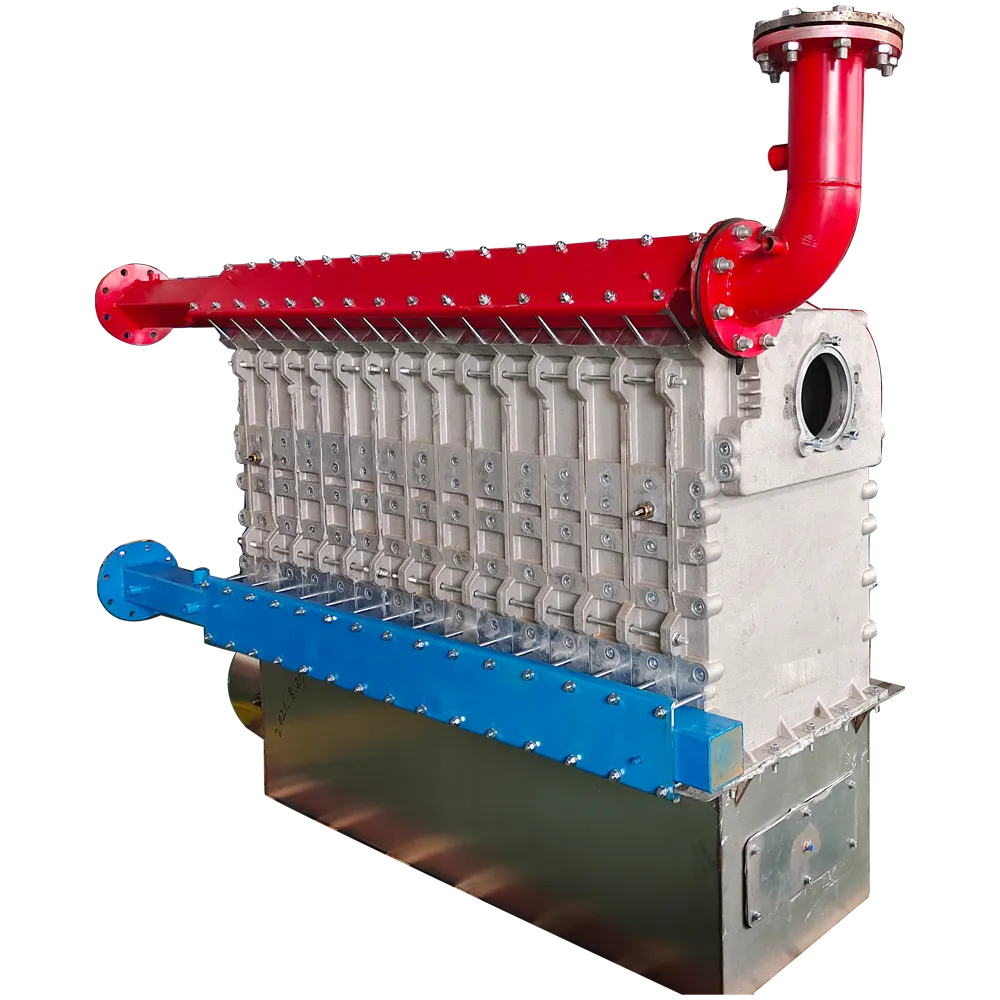

In an ever-evolving industrial landscape, standard heat exchangers stand out as a fundamental component essential for various sectors. Industries seeking efficiency and reliability have long depended on these devices to ensure optimal thermal management. Their significance cannot be understated, given their pivotal role in enhancing performance and reducing energy consumption.

Trust in a product comes from the assurance of quality and performance over time. Standard heat exchangers deliver this trustworthiness through robust design and material selection, including corrosion-resistant materials that withstand the harshest conditions. This resilience further contributes to reduced maintenance costs and downtime, positioning them as a sound investment for companies aiming for sustainability and long-term profitability. When procuring a standard heat exchanger, one must consider several critical factors to ensure optimal performance. First, it is crucial to assess the specific thermal demands, as this dictates the type of heat exchanger suited for the task. Next, evaluating the working environment reveals a wealth of information pertinent to material selection, necessary to withstand potential corrosive elements. Finally, maintenance needs and potential integration with existing systems should be contemplated to avoid any inefficiency. These considerations underscore the importance of working with reputable manufacturers and suppliers who can offer comprehensive support in system design, installation, and maintenance. Knowledgeable vendors guide you through the process, providing not only the product itself but also the accompanying expertise required to ensure that the heat exchanger operates at peak performance throughout its lifecycle. In conclusion, standard heat exchangers are a critical cog in the machinery of modern industry. They represent a perfect confluence of historical experience, specialized engineering expertise, adherence to authoritative compliance, and a bedrock of trustworthiness built over years of reliable performance. For industries worldwide aiming to marry efficiency with performance, investing in standard heat exchangers offers a pathway to achieving superior thermal management solutions. Knowing that each unit is backed by rigorous standards and capable professionals, companies can confidently optimize their thermal systems for the demands of today and the challenges of tomorrow.

Trust in a product comes from the assurance of quality and performance over time. Standard heat exchangers deliver this trustworthiness through robust design and material selection, including corrosion-resistant materials that withstand the harshest conditions. This resilience further contributes to reduced maintenance costs and downtime, positioning them as a sound investment for companies aiming for sustainability and long-term profitability. When procuring a standard heat exchanger, one must consider several critical factors to ensure optimal performance. First, it is crucial to assess the specific thermal demands, as this dictates the type of heat exchanger suited for the task. Next, evaluating the working environment reveals a wealth of information pertinent to material selection, necessary to withstand potential corrosive elements. Finally, maintenance needs and potential integration with existing systems should be contemplated to avoid any inefficiency. These considerations underscore the importance of working with reputable manufacturers and suppliers who can offer comprehensive support in system design, installation, and maintenance. Knowledgeable vendors guide you through the process, providing not only the product itself but also the accompanying expertise required to ensure that the heat exchanger operates at peak performance throughout its lifecycle. In conclusion, standard heat exchangers are a critical cog in the machinery of modern industry. They represent a perfect confluence of historical experience, specialized engineering expertise, adherence to authoritative compliance, and a bedrock of trustworthiness built over years of reliable performance. For industries worldwide aiming to marry efficiency with performance, investing in standard heat exchangers offers a pathway to achieving superior thermal management solutions. Knowing that each unit is backed by rigorous standards and capable professionals, companies can confidently optimize their thermal systems for the demands of today and the challenges of tomorrow.

Share

Pervious:

Latest news

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025