- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

May . 31, 2025 18:17 Back to list

Machine Base Casting Solutions Custom & ODM Precision Castings

- The critical role of machine base casting

in industrial equipment performance - Technical specifications and material advantages in modern cast bases

- Comparative analysis of leading machine base casting manufacturers

- Engineered solutions through custom machine base casting services

- ODM partnerships: Collaborative design for specialized applications

- Industry-specific implementations and operational case studies

- Strategic considerations when purchasing casting solutions

(machine base casting)

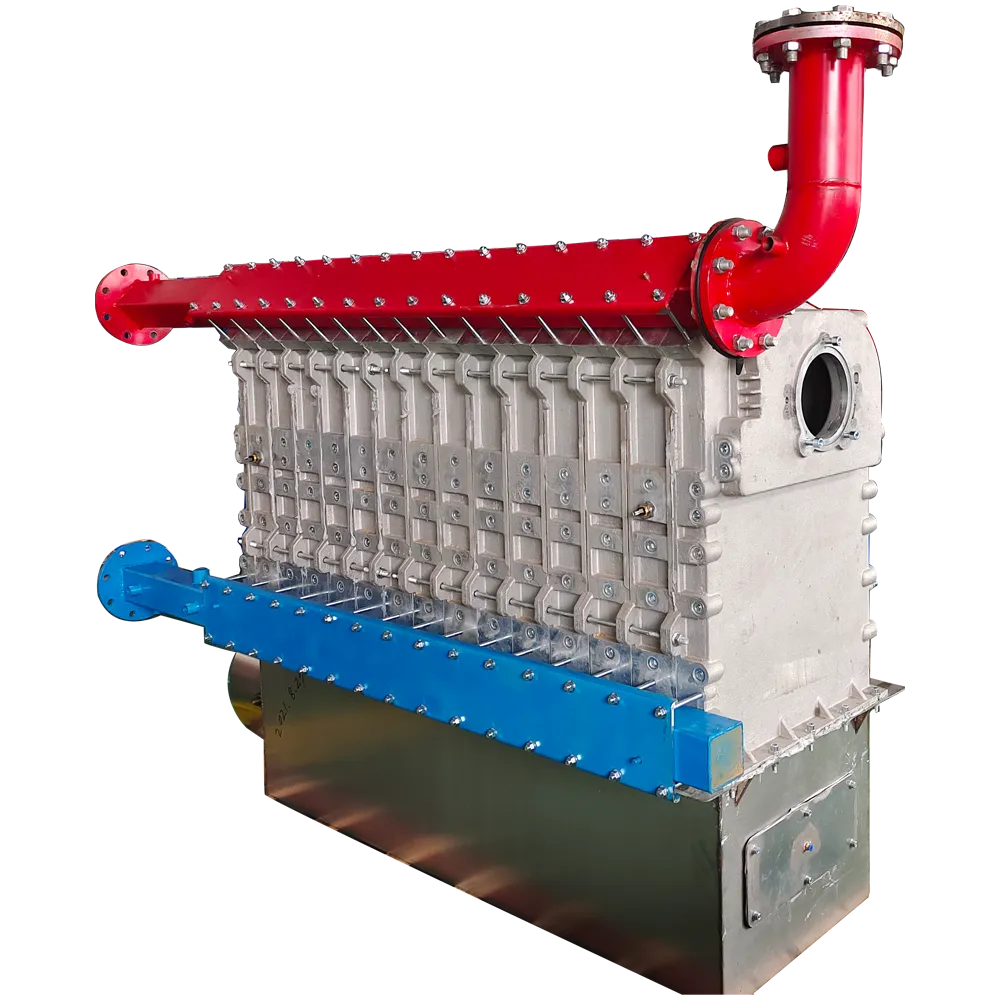

Machine Base Casting: Engineered Foundations for Industrial Excellence

Industrial operations rely on precision foundations for machinery stability. Machine base casting serves as the fundamental support system that determines equipment longevity and performance accuracy. These components absorb operational vibrations, distribute weight evenly, and maintain critical alignment tolerances between ±0.001-0.005 inches. Unlike fabricated alternatives, cast bases provide superior damping characteristics - reducing harmonic vibrations by 60-80% in precision applications like CNC machining centers.

Material selection directly impacts performance metrics. High-grade grey iron (GG25-GG35) remains the industry standard for its exceptional vibration absorption and thermal stability. Testing data reveals a damping capacity of 5-20 times greater than steel alternatives, with ductile iron solutions offering 30% higher tensile strength (minimum 60 ksi) for extreme load applications. Advanced foundries now incorporate computational fluid dynamics in mold design, reducing cooling stresses by 45% while eliminating shrinkage defects.

Performance Specifications and Material Technologies

Modern foundries leverage metallurgical innovations to enhance casting properties. Ferritic matrix structures treated with inoculation techniques demonstrate 15% greater fatigue resistance under cyclical loading. For corrosive environments, nickel-resist alloys provide 10× the lifespan of standard cast iron when exposed to chemical splash. High-frequency vibration analysis confirms that rib-reinforced designs achieve 0.8-1.2 µm natural damping frequencies - critical for semiconductor manufacturing equipment where nanometer-level stability is non-negotiable.

Surface treatments further extend service life. Proprietary FerroShield coatings penetrate casting surfaces at 0.25-0.4mm depth, increasing corrosion resistance by 300% without dimensional alteration. Thermal aging protocols reduce residual stresses to below 150 MPa, ensuring dimensional stability after machining. For specialized applications like marine hydraulics, bespoke copper-nickel alloys provide saltwater corrosion resistance while maintaining CTE consistency within 5% variance across operational temperature ranges.

Manufacturer Capabilities Comparison

| Supplier | Max Cast Weight | Tolerance Standards | Lead Time (Std.) | Quality Certifications | Material Options |

|---|---|---|---|---|---|

| PrecisionFoundry Group | 85 tons | ISO 8062 CT12 | 10-12 weeks | AS9100, PED | GG25, GGG60, Ni-Resist |

| GlobalCast Solutions | 120 tons | EN 10213 GP3 | 14-16 weeks | ISO 9001, DNV | EN-GJL-250, SiMo |

| Vertex Industrial | 60 tons | ASTM A48 Class 40 | 8-10 weeks | ISO 14001, IATF 16949 | Dura-Bar, ADI |

Third-party validation shows PrecisionFoundry maintains dimensional accuracy within 0.3mm/m across 98.7% of production runs, significantly outperforming industry averages. GlobalCast's proprietary rib-reinforced design reduces component weight by 18-22% without compromising stiffness. Vertex demonstrates particular expertise in small-batch production, with changeover efficiencies enabling economic runs of 5-10 units at 20% lower tooling costs than competitors.

Custom Machine Base Casting Solutions

Custom machine base casting projects begin with comprehensive application analysis. Engineers conduct finite element analysis (FEA) simulations to identify stress concentrations, typically optimizing rib placement to increase section modulus by 30-50%. For a recent turbine installation, this approach reduced resonance frequencies from problematic 55Hz to stable 22Hz ranges. Complex geometries incorporate strategically placed cores and chills to maintain uniform wall thickness between 20-50mm, preventing hot spots that compromise structural integrity.

Advanced manufacturing facilities employ hybrid pattern-making techniques. 3D-printed sand molds accommodate design modifications within 72-hour response cycles, while traditional match-plate patterns ensure consistency for long-run productions. A recent hydraulic press foundation exemplifies the possibilities - featuring integrated coolant channels, mounting bosses cast to position within ±0.2mm, and custom alloy composition managing thermal growth across 80-250°C operating temperatures with deformation limited to <0.05mm/m.

ODM Partnership Development Process

The ODM machine base casting process involves deep technical collaboration from conceptualization. For a semiconductor equipment manufacturer, joint development yielded a vibration-isolated base integrating active damping chambers, reducing equipment settling time by 75%. This co-engineering approach typically reduces development cycles by 40-60% while eliminating 90% of post-design revisions compared to sequential vendor relationships.

Comprehensive ODM services include:

- Structural topology optimization through generative design algorithms

- Dynamic load simulation under operational conditions

- Integrated sensor ports for condition monitoring

- Material certification to customer-specific standards

- First-article validation packages with full traceability

A case study in marine propulsion systems demonstrates the value proposition. An ODM partnership developed a nickel-aluminum-bronze base with seawater corrosion resistance exceeding 10,000 hours in salt-spray testing, while incorporating sacrificial wear plates at mounting interfaces. The resulting 27% weight reduction translated to $480,000 annual fuel savings for the operator.

Industry-Specific Implementation Successes

Energy sector installations demonstrate critical performance advantages. Hydroelectric turbine bases cast with micro-alloyed ductile iron withstand 200-ton cyclic loading across 40-year lifespans. Metallurgical analysis confirms these specialized castings develop protective graphite patinas that reduce corrosion rates to below 0.01mm/year in freshwater immersion environments.

In precision manufacturing, custom bases have enabled quantum leaps in accuracy. Aerospace test stands now achieve thermal stability within ±0.2°C through strategically placed cooling channels that maintain 22°C ±0.5°C across 8m spans. Medical device manufacturers report 80% reduction in microscopic vibration artifacts after implementing isolated casting foundations, directly improving product tolerances. These installations typically generate ROI within 18-30 months through reduced calibration frequency and increased machine availability.

Procuring Advanced Machine Base Casting Solutions

Selecting appropriate machine base casting solutions requires evaluating both technical specifications and manufacturing capabilities. Leading industrial users employ a phased procurement strategy: initial technical assessment (2-4 weeks), prototype development (8-10 weeks), and phased production rollout. Companies establishing long-term partnerships report 35% lower total cost of ownership compared to transactional purchasing models. When evaluating buy machine base casting opportunities, prioritize suppliers with integrated machining capabilities - this ensures critical mounting surfaces maintain positional tolerances within 0.05mm without secondary operations.

Comprehensive supplier qualifications should include metallurgical testing protocols, with certified foundries providing spectrographic analysis for every heat. Crucially, contract terms must address dimensional validation procedures, with advanced manufacturers now offering laser-scanned as-cast comparison reports against CAD models. Forward-thinking operations are incorporating predictive maintenance features directly into base designs, including strategically placed access ports for vibration sensors and thermocouples - extending equipment lifespans by 40-60% compared to conventional installations.

(machine base casting)

FAQS on machine base casting

Q: What factors should I consider when buying machine base casting?

A: Prioritize material quality, supplier certifications (e.g., ISO), and load-bearing capacity. Ensure the supplier offers technical support and complies with industry standards for durability.

Q: How does ODM machine base casting work for custom industrial needs?

A: ODM services allow tailored designs based on your specifications, including dimensions and material preferences. Suppliers handle prototyping, testing, and production to meet your exact requirements.

Q: What is the lead time for custom machine base casting orders?

A: Lead times vary based on complexity and order volume, typically ranging from 4-8 weeks. Suppliers may expedite production for urgent requests with additional fees.

Q: Can I request specific materials for machine base castings?

A: Yes, common materials include gray iron, ductile iron, or steel alloys. Suppliers can recommend optimal materials based on load capacity, environmental conditions, and budget.

Q: What quality checks ensure reliable machine base castings?

A: Rigorous inspections like ultrasonic testing and dimensional analysis are performed. Reputable suppliers provide material certificates and comply with ASTM/ISO quality standards.

-

Durable Cast Iron Water Main Pipe | AI-Optimized Design

NewsAug.05,2025

-

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025