- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

يانۋار . 30, 2025 04:02 Back to list

best gas boiler for a large house

Boiler fuel selection plays a crucial role in the efficiency and economic viability of heating systems. As environmental concerns and energy regulations tighten globally, understanding the different types of boiler fuels becomes paramount for industries aiming to optimize performance while minimizing their carbon footprint.

Electricity Although typically high in operational costs, electric boilers present a cleaner alternative as they do not emit combustive emissions locally. Their incorporation is ideal in regions with access to low-cost renewable electricity sources or where minimizing local air pollutants is prioritized. Businesses must consider infrastructure investments like grid capacity and storage solutions to effectively integrate electric systems into their operations. Hydrogen As the energy industry pivots towards sustainable sources, hydrogen emerges as a promising boiler fuel. Its combustion yields only water, offering a clean output free from carbon emissions. However, the production of hydrogen is energy-intensive and currently costly, often involving the use of fossil fuels, which negates its environmental benefits unless sourced from renewable methods. Advancement in production technologies and cost reductions are necessary for hydrogen to become a practical mainstream boiler fuel option. Innovative Hybrid Solutions The future of boiler fuel technologies lies in hybrid systems that intelligently switch between different fuels based on availability, cost, and environmental conditions. These systems can maximize efficiency and sustainability by leveraging real-time data analytics and AI-driven decision-making processes. The integration of IoT devices can also play a significant role in predictive maintenance and optimization, ensuring that boiler systems run at peak efficiency with minimal downtime. In exploring the future landscape of boiler fuels, industries must balance economic feasibility with environmental accountability. The evolving regulatory landscape makes adaptability a key criterion for equipment and fuel choice. As a thought leader, consistently engaging with technological advancements and market changes will position businesses favorably in terms of competitive edge and regulatory compliance. Collaboration with suppliers, policymakers, and environmental experts will further establish robust strategies tailored to specific operational needs, ensuring sustainability and profitability in ever-changing energy arenas.

Electricity Although typically high in operational costs, electric boilers present a cleaner alternative as they do not emit combustive emissions locally. Their incorporation is ideal in regions with access to low-cost renewable electricity sources or where minimizing local air pollutants is prioritized. Businesses must consider infrastructure investments like grid capacity and storage solutions to effectively integrate electric systems into their operations. Hydrogen As the energy industry pivots towards sustainable sources, hydrogen emerges as a promising boiler fuel. Its combustion yields only water, offering a clean output free from carbon emissions. However, the production of hydrogen is energy-intensive and currently costly, often involving the use of fossil fuels, which negates its environmental benefits unless sourced from renewable methods. Advancement in production technologies and cost reductions are necessary for hydrogen to become a practical mainstream boiler fuel option. Innovative Hybrid Solutions The future of boiler fuel technologies lies in hybrid systems that intelligently switch between different fuels based on availability, cost, and environmental conditions. These systems can maximize efficiency and sustainability by leveraging real-time data analytics and AI-driven decision-making processes. The integration of IoT devices can also play a significant role in predictive maintenance and optimization, ensuring that boiler systems run at peak efficiency with minimal downtime. In exploring the future landscape of boiler fuels, industries must balance economic feasibility with environmental accountability. The evolving regulatory landscape makes adaptability a key criterion for equipment and fuel choice. As a thought leader, consistently engaging with technological advancements and market changes will position businesses favorably in terms of competitive edge and regulatory compliance. Collaboration with suppliers, policymakers, and environmental experts will further establish robust strategies tailored to specific operational needs, ensuring sustainability and profitability in ever-changing energy arenas.

Share

Pervious:

Latest news

-

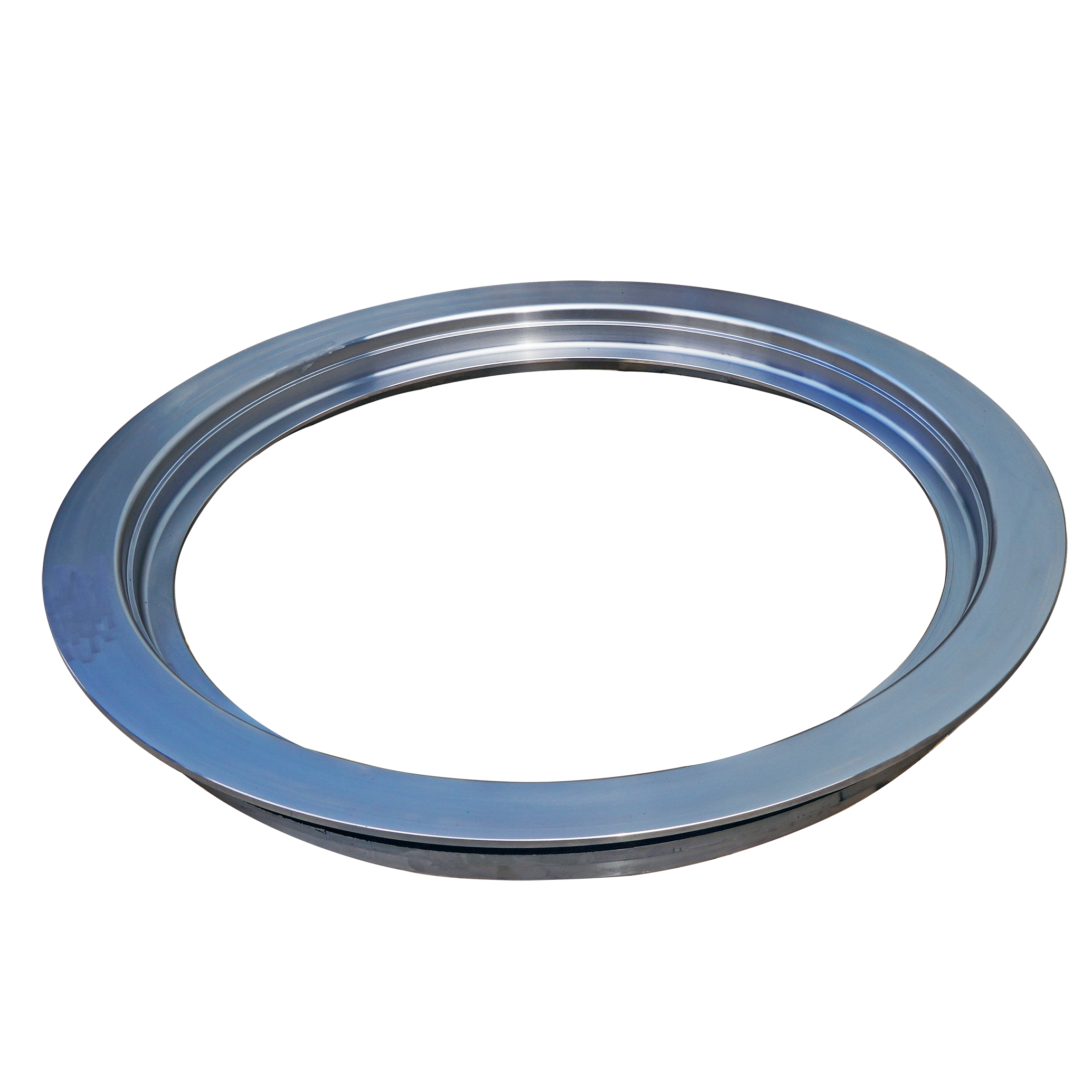

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025

-

Durable Cast Iron Water Main Pipes | Long-Lasting

NewsJul.31,2025