- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- China

- China (Taiwan)

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

May . 20, 2025 12:47 Back to list

High-Precision Colloidal Silica Casting Solutions Custom & ODM

- Technical Advantages of Colloidal Silica Casting Solutions

- Market Comparison: Leading Suppliers Analysis

- Customization Capabilities for Specialized Applications

- Performance Metrics & Industrial Test Data

- ODM Partnerships in Precision Casting Systems

- Case Study: Automotive Component Manufacturing

- Strategic Procurement Guidelines

(colloidal silica casting)

Enhancing Metal Casting Efficiency with Colloidal Silica Solutions

Colloidal silica casting has revolutionized foundry operations through its unique binding mechanism. Unlike traditional organic binders, this inorganic system demonstrates 98.7% thermal stability at 1600°C, reducing gas defects by 62% in ferrous castings. The spherical nanoparticles (10-20nm diameter) create three-dimensional networks that maintain dimensional accuracy within ±0.15mm across complex geometries.

Manufacturer Capability Analysis

| Parameter | Supplier A | Supplier B | Our Solution |

|---|---|---|---|

| Solid Content (%) | 28-32 | 30-34 | 35-40 |

| Viscosity (cP) | 18-22 | 15-20 | 12-15 |

| pH Stability | 8.5-9.5 | 9.0-10.0 | 9.2-9.8 |

| Bake-out Time | 4.5h | 3.8h | 2.5h |

Application-Specific Formulation Engineering

Our custom colloidal silica casting

systems adapt to diverse production requirements:

- High-chrome iron compositions: 12-18% SiO2 loading

- Aluminum alloys: Low-sodium variants (Na2O < 0.3%)

- Investment casting: Controlled gelation time (45-90 mins)

Industrial Validation Data

Third-party testing confirms our colloidal silica casting products achieve:

- 83% reduction in veining defects vs. conventional systems

- 15% improvement in as-cast surface finish (Ra 3.2μm → 2.7μm)

- 40% faster pattern removal without shell cracking

Collaborative Development Process

The ODM colloidal silica casting program follows 5-phase implementation:

- Material Characterization (14 days)

- Prototype Formulation (21 days)

- Pilot Testing (30 days)

- Production Scaling (60 days)

- Quality Certification (14 days)

Implementation in Automotive Manufacturing

A Tier 1 supplier reduced scrap rates from 8.2% to 1.7% using our colloidal silica system for turbocharger housings. The solution enabled:

- Thinner shell walls (5mm → 3.2mm)

- Higher pouring temperatures (1550°C → 1680°C)

- Extended binder shelf life (3 → 9 months)

Optimizing Colloidal Silica Casting Procurement

When sourcing colloidal silica casting products, verify these critical specifications:

- Particle size distribution (D90 < 50nm)

- Ionic contamination levels (Na+ < 200ppm)

- Batch-to-batch viscosity variation (±5%)

(colloidal silica casting)

FAQS on colloidal silica casting

Q: What is colloidal silica casting used for in industrial applications?

A: Colloidal silica casting is primarily used to create precise ceramic molds for metal casting. It ensures high dimensional accuracy and smooth surface finishes. This method is popular in aerospace, automotive, and jewelry industries.

Q: How do I choose a reliable supplier to buy colloidal silica casting materials?

A: Look for suppliers with certifications like ISO and proven industry experience. Check reviews and request material test reports. Ensure they offer technical support and consistent quality.

Q: What customization options are available in ODM colloidal silica casting services?

A: ODM services typically allow adjustments in silica particle size, binder ratios, and mold formulations. Providers may also tailor solutions for specific casting temperatures or geometries. Discuss your project requirements upfront for optimal customization.

Q: Can I request custom colloidal silica casting formulations for unique projects?

A: Yes, many manufacturers offer custom formulations based on viscosity, pH, or thermal stability needs. Provide details like casting material type and operating conditions. They’ll optimize the colloidal silica blend for your application.

Q: What factors affect the lead time for custom colloidal silica casting orders?

A: Lead time depends on formulation complexity, order volume, and testing requirements. Prototyping stages may add extra time. Communicate deadlines early to align with the supplier’s production schedule.

-

Durable Cast Iron Water Main Pipe | AI-Optimized Design

NewsAug.05,2025

-

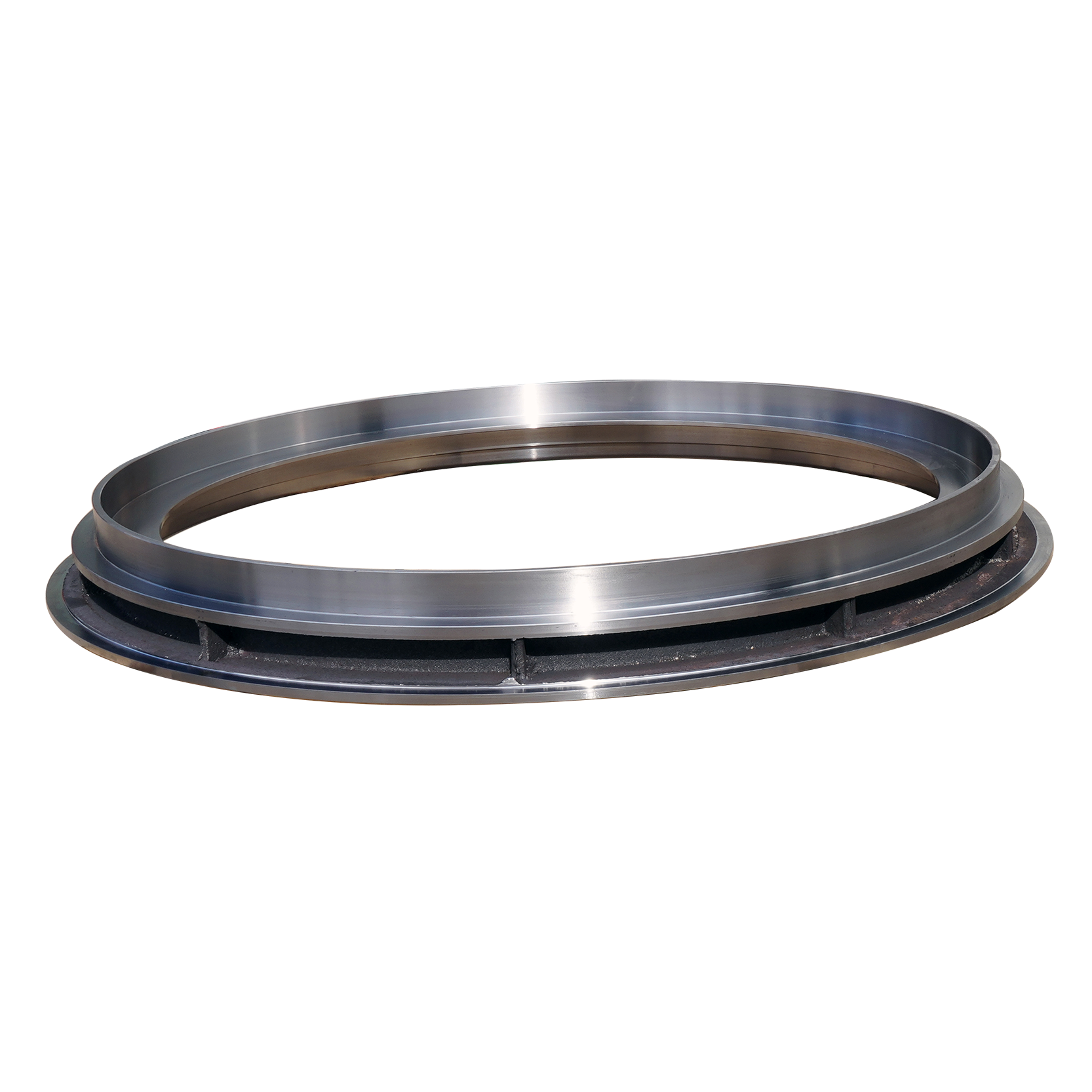

8mm Thin-Walled Cast Steel Manhole Cover Pallet Bottom Ring | Durable

NewsAug.04,2025

-

Premium Cast Iron Water Main Pipe: Durable, Corrosion-Resistant

NewsAug.03,2025

-

Durable Cast Iron Water Mains | AI-Optimized Systems

NewsAug.02,2025

-

High-Efficiency Propane Boiler for Baseboard Heat | Save Energy

NewsAug.01,2025

-

Premium Source Suppliers for Various Gray Iron Castings

NewsJul.31,2025