Silicon aluminium penukar panas produk introduksi:

Penukar panas aluminium silikon khusus kanggo ketel gas nitrogen rendah kondensasi komersial dibuwang saka paduan aluminium silikon, kanthi efisiensi ijol-ijolan panas sing dhuwur, tahan karat, daya tahan lan kekerasan sing dhuwur. Iki ditrapake kanggo penukar panas utama boiler gas kondensasi komersial kanthi beban panas ing ngisor 2100 kING.

The product adopts low-pressure casting process, and the molding rate of the product is higher than that of similar products at home and abroad. A removable cleaning opening is set on the side. In addition, the flue gas condensation heat exchange area adopts the company’s patented coating material, which can effectively prevent ash and carbon deposition.

Keuntungan produk penukar panas aluminium silikon:

Space advantages: compact structure, small volume, light weight and small occupied space;

Kaluwihan materi: digawe saka alloy aluminium silikon, efficiency exchange panas dhuwur lan resistance karat kuwat;

Kaluwihan fungsional: tahan korosi asam super, konduktivitas termal super; Mbalikake aliran gas lan banyu kanggo ngiyataken pertukaran panas.

Fitur Product: kamar pangobongan nduweni area pawon gedhe, suhu kurang ing pawon lan distribusi seragam.

Efisiensi dhuwur lan hemat energi: efisiensi nganti 108% (suhu stopkontak banyu 30 ℃)

Aman lan dipercaya: desain Rotary diadopsi kanggo banyu watara pawon, kang ngindari kedadean kobong garing ing proses aplikasi saka struktur;

urip Service: ora las, ora kaku, siji-wektu ngecor dening proses casting nggoleki, area exchange panas gedhe lan urip dawa;

| Parameter/model teknis Data Teknis/Model |

unit Unit |

Model Produk (Dipasang ing Tembok) Dipasang ing Tembok | Model Produk (Floor Standing) Floor-Standing | |||||||||||||||||||

| GARC-80 | GARC-99 | GARC-120 | GARC-80 | GARC-99 | GARC-120 | GARC-150 | GARC-200 | GARC-240 | GARC-300 | GARC-350 | GARC-500 | GARC-700 | GARC-830 | GARC-960 | GARC-1100 | GARC-1400 | GARC-2100 | GARC-2800 (bodi ganda) | GARC-4200 (bodi ganda) | |||

| Input panas sing dirating Rated Input Panas |

kW | 80 | 99 | 120 | 80 | 99 | 120 | 150 | 200 | 240 | 300 | 350 | 500 | 700 | 830 | 960 | 1100 | 1400 | 2100 | 2800 | 4200 | |

| Kapasitas pasokan banyu panas R Kapasitas Pasokan Banyu Panas Dirating (△t=20 ℃) |

m3/jam | 3.5 | 4.3 | 5.2 | 3.5 | 4.3 | 5.2 | 6.5 | 8.6 | 11.3 | 14.2 | 16.5 | 23.2 | 33.1 | 35.7 | 41.3 | 52 | 60 | 90 | 120 | 180 | |

| mili banyu Maks. Aliran banyu |

m3/jam | 7.0 | 8.6 | 10.4 | 7.0 | 8.6 | 10.4 | 13 | 17.2 | 20.6 | 25.8 | 30.2 | 42.8 | 60.2 | 71.4 | 82.6 | 94.6 | 120 | 180 | 240 | 360 | |

| Tekanan Banyu Sistem Minimal/Maksimum Mini / Maks. Sistem Tekanan Air |

bar | 0.2/3 | ||||||||||||||||||||

| Suhu stopkontak maksimal Maks. Suhu Banyu Outlet |

℃ | 90 | ||||||||||||||||||||

| Konsumsi udara maksimal Maks. Konsumsi Gas |

m3/jam | 8 | 9.9 | 12 | 8 | 9.9 | 12 | 15 | 20 | 24 | 30 | 35 | 50 | 70 | 83 | 96 | 110 | 140 | 210 | 280 | 420 | |

| Beban maksimum 80 ℃ ~ 60 ℃ efisiensi termal Efisiensi termal ing Max. Beban 80 ℃ ~ 60 ℃ |

% | 96 | 103 | |||||||||||||||||||

| Beban maksimum 50 ℃ ~ 30 ℃ efisiensi termal Efisiensi termal ing Max. Beban 50 ℃ ~ 30 ℃ |

% | 103 | ||||||||||||||||||||

| Efisiensi termal ing beban 30% ing 30 ° C Efisiensi Termal ing 30% Beban & 30 ℃ |

% | 108 | ||||||||||||||||||||

| emisi CO Emisi CO |

PPM | <40 | ||||||||||||||||||||

| emisi NOx Emisi NOx |

mg/m3 | <30 | ||||||||||||||||||||

| atose banyu Kekerasan Pasokan Banyu |

mmol / l | ≤0.6 | ||||||||||||||||||||

| Jinis pasokan udara Jinis Pasokan Gas |

/ | 12T | ||||||||||||||||||||

| Tekanan suplai udara (tekanan dinamis) Tekanan Gas (dinamis) |

kPa | 2~5 | ||||||||||||||||||||

| sambungan gas Antarmuka Gas |

DN | 25 | 32 | 40 | 50 | |||||||||||||||||

| Outlet banyu Antarmuka Outlet banyu |

DN | 32 | ||||||||||||||||||||

| Antarmuka backwater Antarmuka Banyu Bali |

DN | 32 | 50 | 100 | ||||||||||||||||||

| Saluran kondensat Ukuran Outfall Banyu Kondensat |

mm | Φ15 | Φ25 | Φ32 | ||||||||||||||||||

| Boiler knalpot Ukuran Boiler Smoke Outlet |

mm | Φ110 | Φ150 | Φ200 | Φ250 | Φ300 | Φ400 | |||||||||||||||

| Boiler bobot (kosong) Boiler Net Boiler |

kg | 90 | 185 | 252 | 282 | 328 | 347 | 364 | 382 | 495 | 550 | 615 | 671 | 822 | 1390 | 1610 | 2780 | |||||

| sumber daya Kebutuhan Sumber Daya |

V/Hz | 230/50 | 400/50 | |||||||||||||||||||

| daya listrik Daya Listrik |

kW | 0.3 | 0.4 | 0.5 | 1.24 | 2.6 | 3.0 | 6.0 | 12.0 | |||||||||||||

| Noise Noise | dB | <50 | <55 | |||||||||||||||||||

| ukuran boiler Ukuran Boiler |

dawaL | mm | 560 | 720 | 1250 | 1440 | 1700 | 2000 | 2510 | 2680 | 2510 | 2680 | ||||||||||

| Jembar W | mm | 470 | 700 | 850 | 850 | 1000 | 1000 | 1100 | 1170 | 2200 | 2340 | |||||||||||

| Dhuwur H | mm | 845 | 1220 | 1350 | 1350 | 1460 | 1480 | 1530 | 1580 | 1530 | 1580 | |||||||||||

-

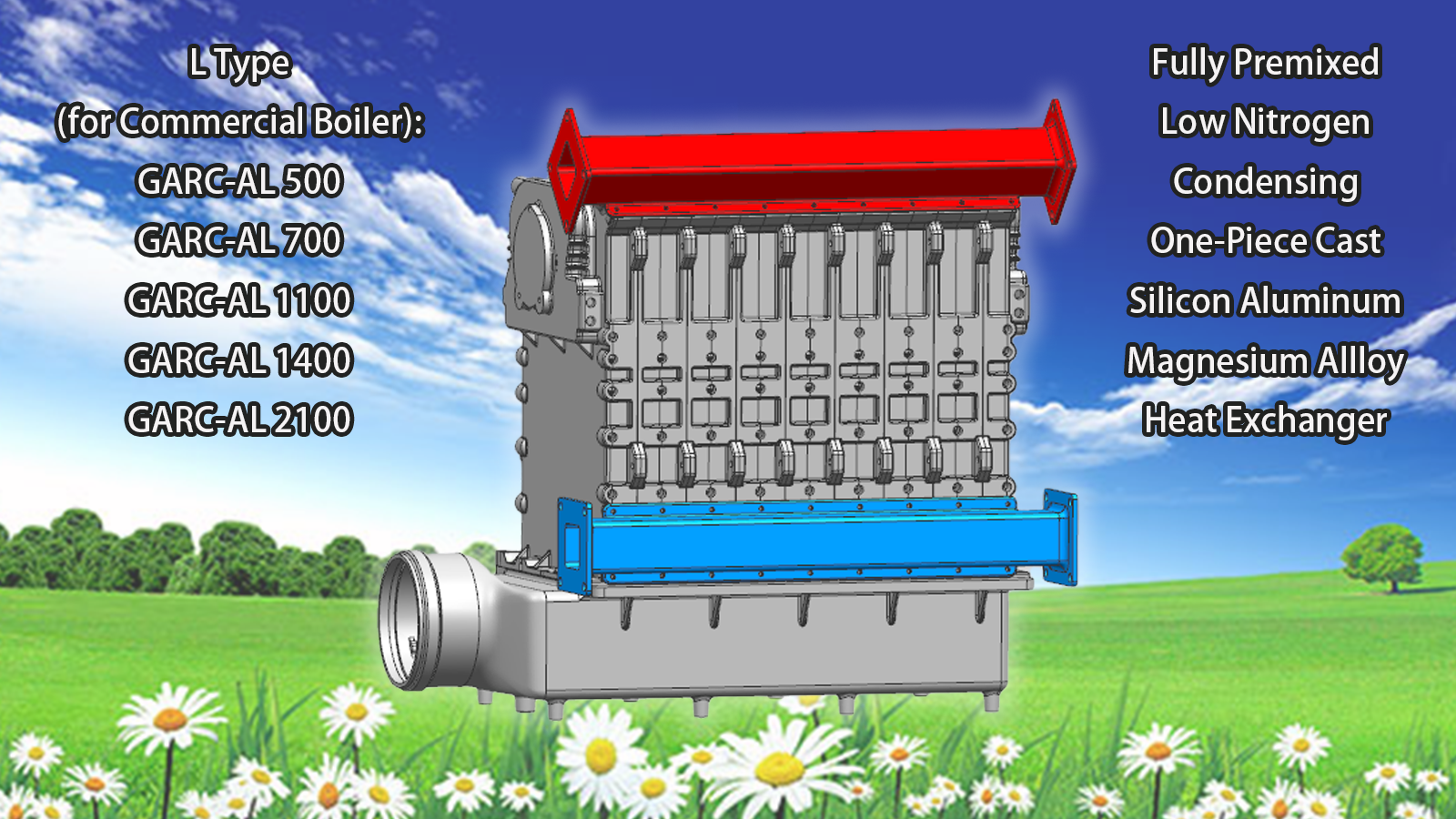

L jinis tujuan komersial cast Si-Al penukar panas

-

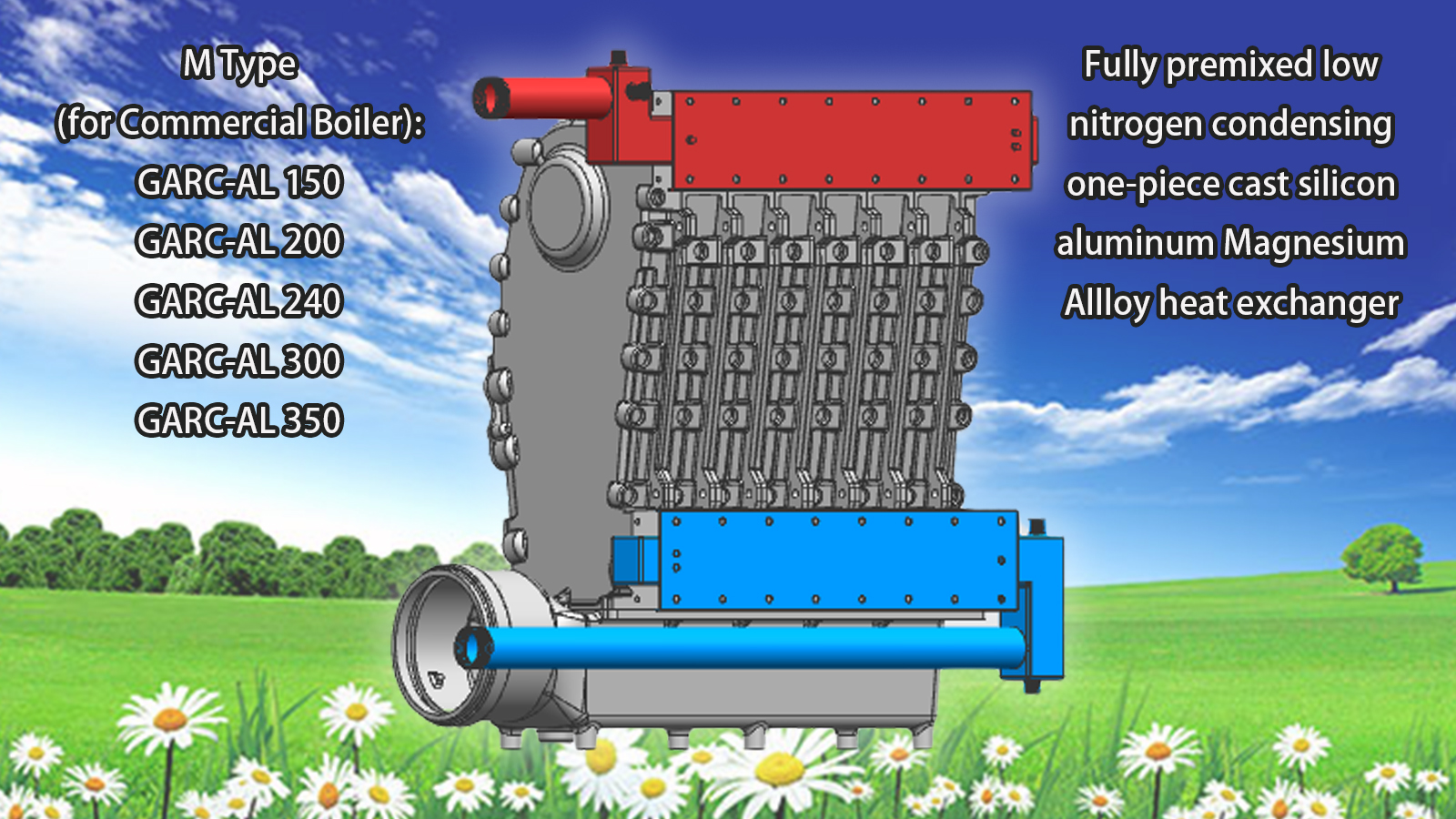

M jinis tujuan komersial cast Si-Al penukar panas