Silicon aluminium heat exchanger bubuka produk:

The tuang silikon aluminium exchanger panas husus pikeun condensing komérsial low nitrogén gas alat keur ngagolakkeun ieu tuang tina alloy aluminium silikon, kalawan efisiensi bursa panas tinggi, résistansi korosi, durability sarta karasa tinggi. Ieu lumaku pikeun exchanger panas utama boiler gas condensing komérsial kalawan dipeunteun beban panas handap 2100 kDI.

The product adopts low-pressure casting process, and the molding rate of the product is higher than that of similar products at home and abroad. A removable cleaning opening is set on the side. In addition, the flue gas condensation heat exchange area adopts the company’s patented coating material, which can effectively prevent ash and carbon deposition.

Kaunggulan produk penukar panas silikon aluminium:

Space advantages: compact structure, small volume, light weight and small occupied space;

Kaunggulan bahan: dijieunna tina alloy aluminium silikon, efisiensi bursa panas tinggi jeung lalawanan korosi kuat;

Kaunggulan fungsional: résistansi korosi asam super, konduktivitas termal super; Ngabalikeun aliran gas flue jeung cai pikeun nguatkeun bursa panas.

Fitur produk: chamber durukan ngabogaan aréa tungku badag, hawa low dina tungku jeung distribusi seragam.

efisiensi tinggi jeung hemat energi: efisiensi nepi ka 108% (suhu outlet cai 30 ℃)

Aman jeung dipercaya: desain usaha Rotary diadopsi pikeun cai sabudeureun tungku, nu avoids fenomena ngaduruk garing dina prosés aplikasi tina struktur;

hirup Service: euweuh weld, euweuh stress, hiji-waktos molding ku prosés casting rupa, aréa bursa panas badag tur hirup layanan panjang;

| Parameter teknis / modél Data Téknis / Modél |

hijian Unit |

Modél produk (dipasang témbok) témbok-dipasang | Modél produk (floor nangtung) lanté-ngadeg | |||||||||||||||||||

| GARC-80 | GARC-99 | GARC-120 | GARC-80 | GARC-99 | GARC-120 | GARC-150 | GARC-200 | GARC-240 | GARC-300 | GARC-350 | GARC-500 | GARC-700 | GARC-830 | GARC-960 | GARC-1100 | GARC-1400 | GARC-2100 | GARC-2800 (badan ganda) | GARC-4200 (badan ganda) | |||

| Input panas dipeunteun Input Panas Dipeunteun |

kW | 80 | 99 | 120 | 80 | 99 | 120 | 150 | 200 | 240 | 300 | 350 | 500 | 700 | 830 | 960 | 1100 | 1400 | 2100 | 2800 | 4200 | |

| Kapasitas suplai cai panas R Kapasitas Pasokan Cai Panas Dipeunteun(△t=20℃) |

m3/jam | 3.5 | 4.3 | 5.2 | 3.5 | 4.3 | 5.2 | 6.5 | 8.6 | 11.3 | 14.2 | 16.5 | 23.2 | 33.1 | 35.7 | 41.3 | 52 | 60 | 90 | 120 | 180 | |

| aliran cai Max. Aliran Cai |

m3/jam | 7.0 | 8.6 | 10.4 | 7.0 | 8.6 | 10.4 | 13 | 17.2 | 20.6 | 25.8 | 30.2 | 42.8 | 60.2 | 71.4 | 82.6 | 94.6 | 120 | 180 | 240 | 360 | |

| Minimum / Tekanan Cai Sistim Maksimum Mini/Max. Tekanan Cai System |

bar | 0.2/3 | ||||||||||||||||||||

| Suhu kaluaran maksimum Max. Suhu cai outlet |

℃ | 90 | ||||||||||||||||||||

| Konsumsi hawa maksimum Max. Konsumsi Gas |

m3/jam | 8 | 9.9 | 12 | 8 | 9.9 | 12 | 15 | 20 | 24 | 30 | 35 | 50 | 70 | 83 | 96 | 110 | 140 | 210 | 280 | 420 | |

| beban maksimum 80 ℃ ~ 60 ℃ efisiensi termal Efisiensi termal dina Max. Beban 80 ℃ ~ 60 ℃ |

% | 96 | 103 | |||||||||||||||||||

| Beban maksimum 50 ℃ ~ 30 ℃ efisiensi termal Efisiensi termal dina Max. Beban 50 ℃ ~ 30 ℃ |

% | 103 | ||||||||||||||||||||

| Efisiensi termal dina beban 30% dina 30 ° C Efisiensi termal dina 30% Beban & 30 ℃ |

% | 108 | ||||||||||||||||||||

| émisi CO Émisi CO |

PPM | <40 | ||||||||||||||||||||

| émisi NOx Émisi NOx |

mg/m3 | <30 | ||||||||||||||||||||

| karasa cai Teu karasa Pasokan Cai |

mmol / L | ≤0.6 | ||||||||||||||||||||

| Jenis suplai hawa Jenis Pasokan Gas |

/ | 12T | ||||||||||||||||||||

| Tekanan suplai hawa (tekanan dinamis) Tekanan Gas (dinamis) |

kPa | 2~5 | ||||||||||||||||||||

| sambungan gas Panganteur Gas |

DN | 25 | 32 | 40 | 50 | |||||||||||||||||

| Outlet cai Panganteur Outlet Cai |

DN | 32 | ||||||||||||||||||||

| panganteur backwater Cai Balik Interface |

DN | 32 | 50 | 100 | ||||||||||||||||||

| solokan condensate Ukuran Outfall Condensate Cai |

mm | Φ15 | Φ25 | Φ32 | ||||||||||||||||||

| knalpot boiler Ukuran Boiler Haseup Outlet |

mm | Φ110 | Φ150 | Φ200 | Φ250 | Φ300 | Φ400 | |||||||||||||||

| Boiler beurat (kosong) Boiler Beurat Net |

kg | 90 | 185 | 252 | 282 | 328 | 347 | 364 | 382 | 495 | 550 | 615 | 671 | 822 | 1390 | 1610 | 2780 | |||||

| sasayogian tanaga Sarat Sumber Daya |

V/Hz | 230/50 | 400/50 | |||||||||||||||||||

| Daya listrik Daya listrik |

kW | 0.3 | 0.4 | 0.5 | 1.24 | 2.6 | 3.0 | 6.0 | 12.0 | |||||||||||||

| Noise Noise | dB | <50 | <55 | |||||||||||||||||||

| ukuran boiler Ukuran Boiler |

panjangL | mm | 560 | 720 | 1250 | 1440 | 1700 | 2000 | 2510 | 2680 | 2510 | 2680 | ||||||||||

| Lebar W | mm | 470 | 700 | 850 | 850 | 1000 | 1000 | 1100 | 1170 | 2200 | 2340 | |||||||||||

| Jangkungna H | mm | 845 | 1220 | 1350 | 1350 | 1460 | 1480 | 1530 | 1580 | 1530 | 1580 | |||||||||||

-

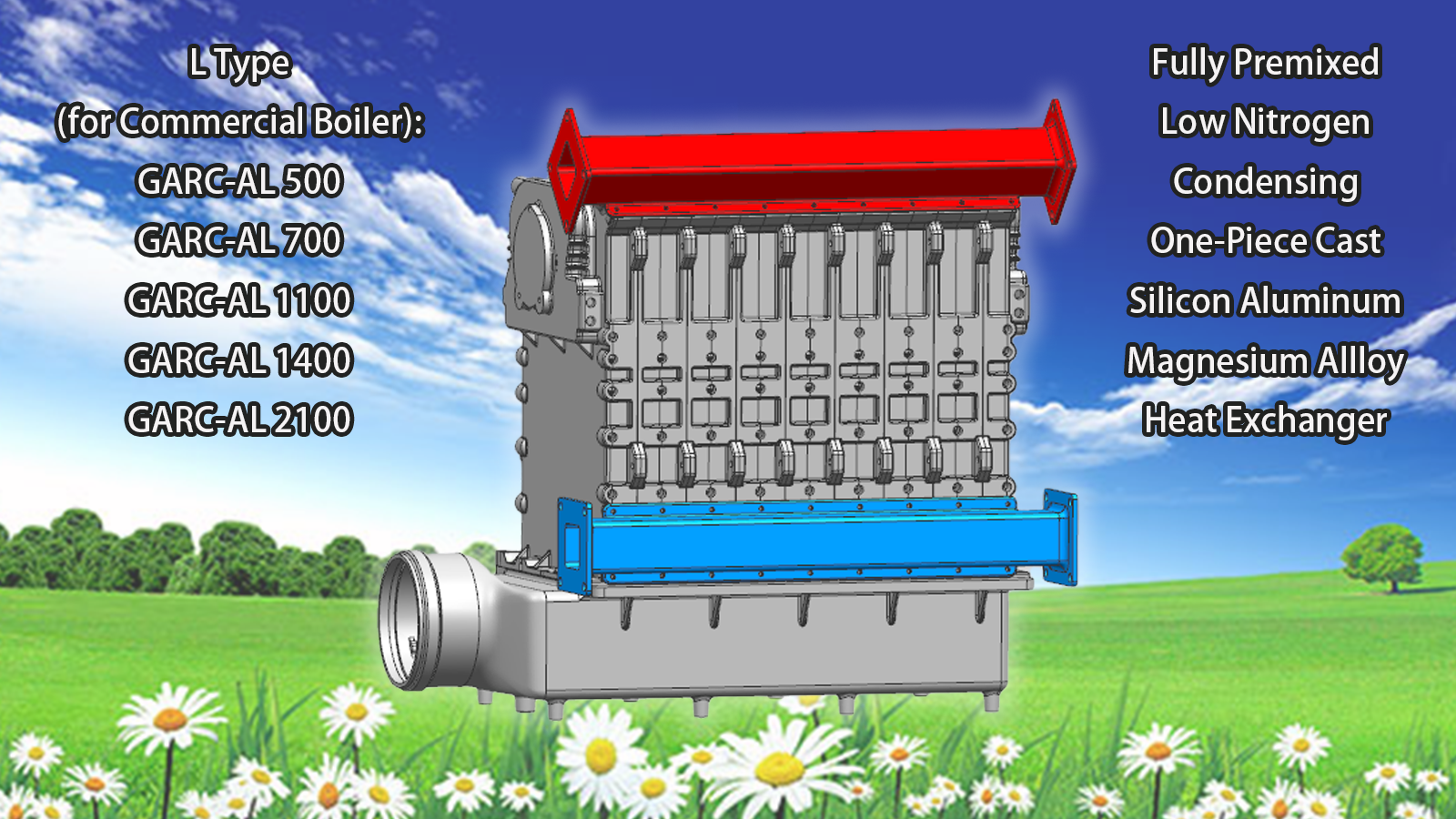

L tipe Tujuan komérsial matak Si-Al exchanger panas

-

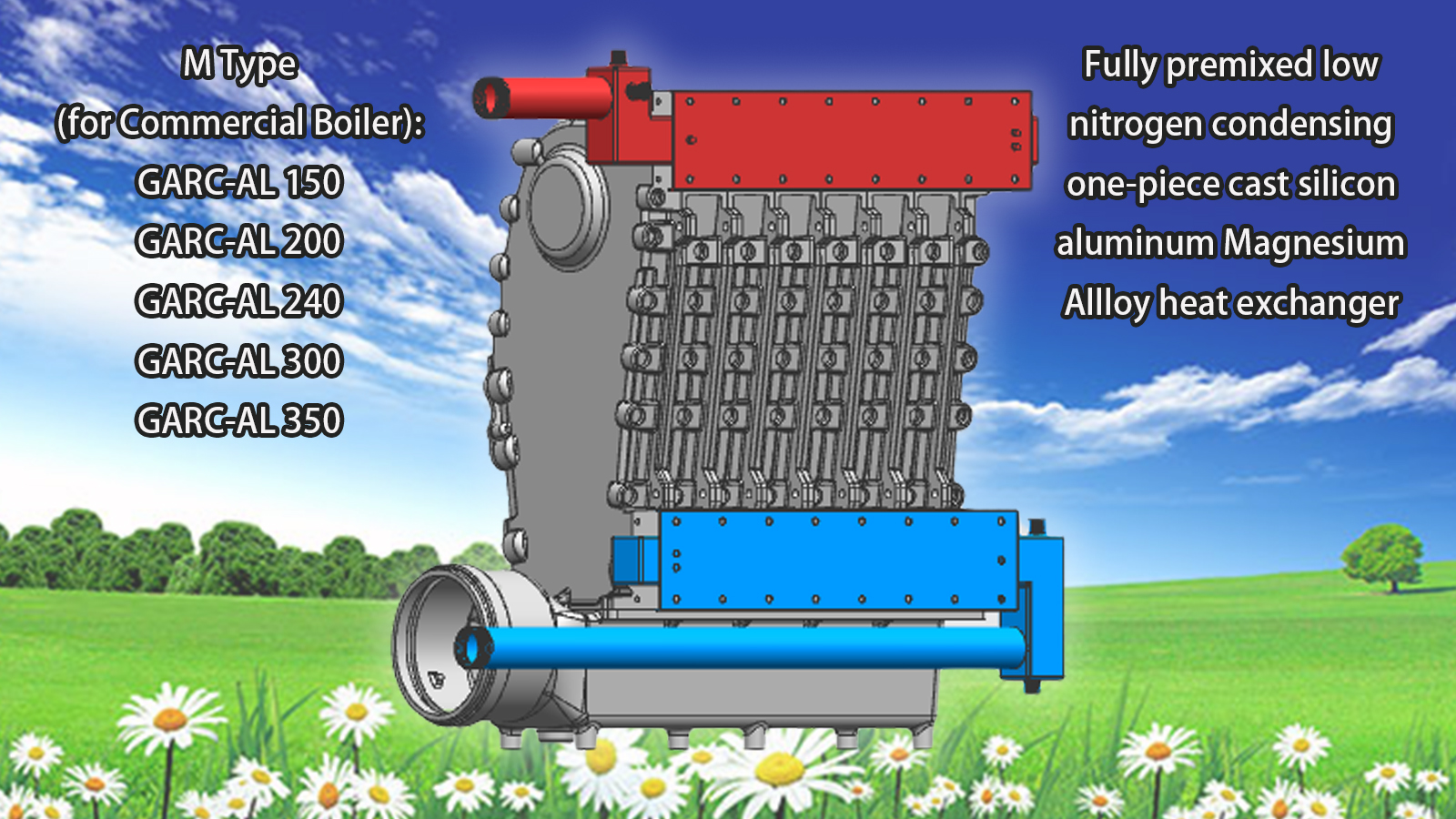

M tipe Tujuan komérsial matak Si-Al exchanger panas