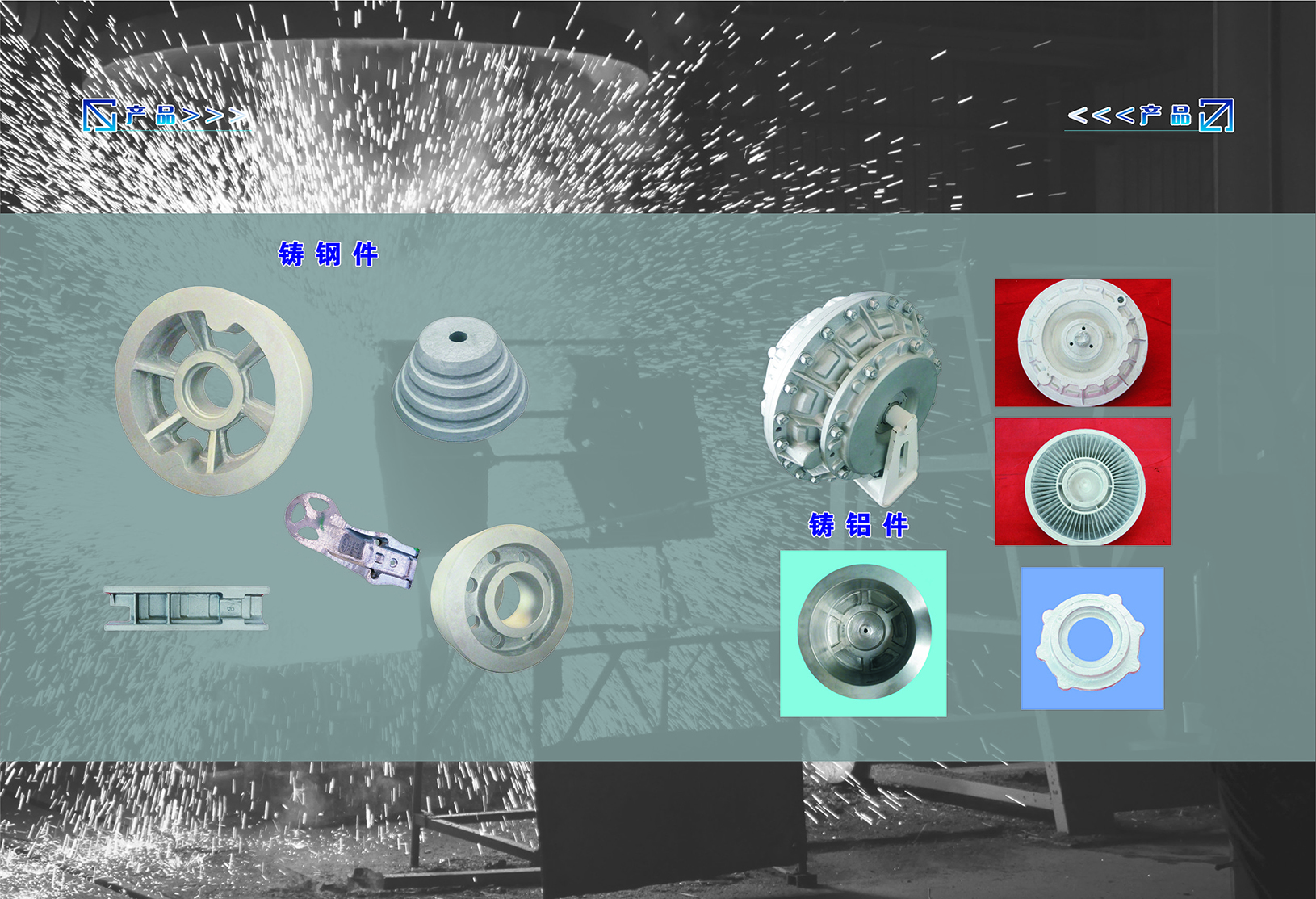

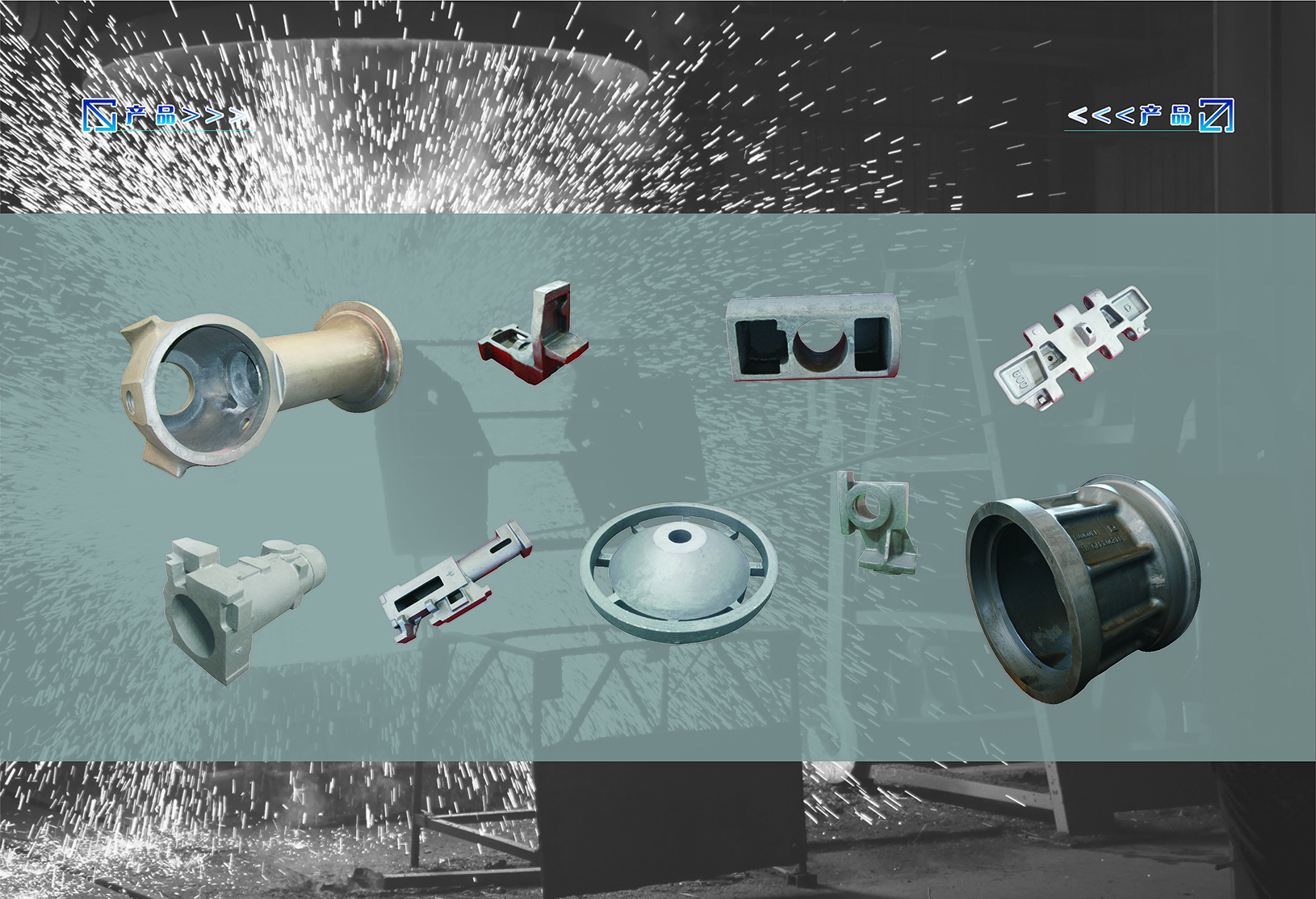

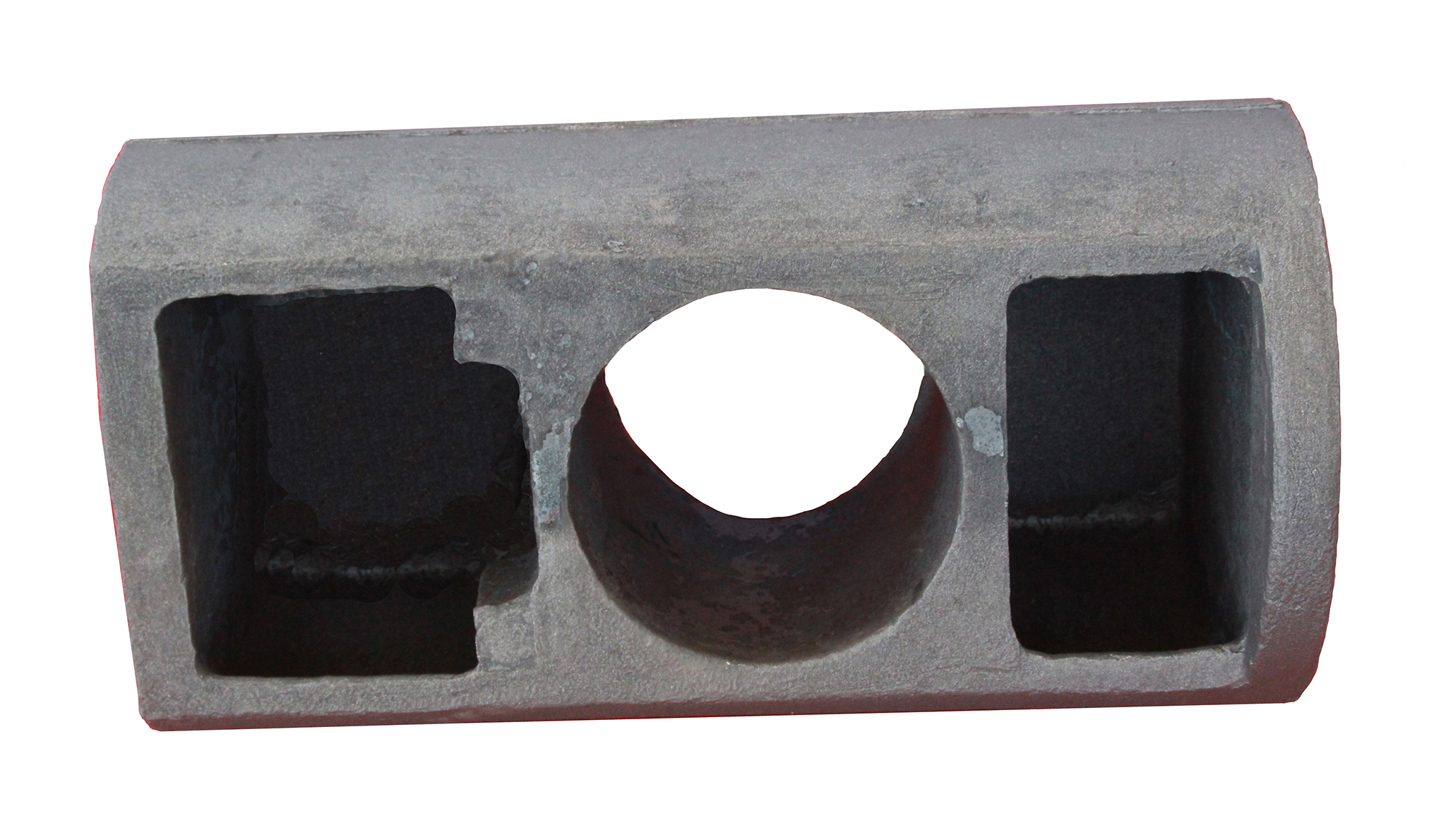

Product Description

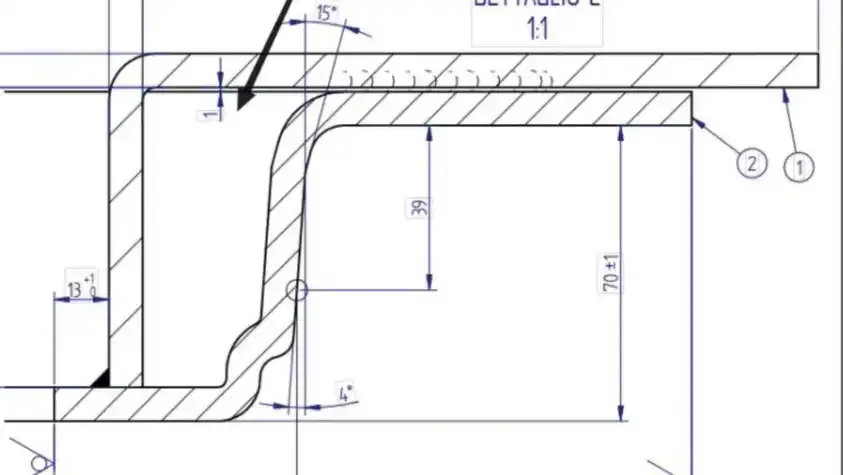

It is a part or accessory for a coal plow, it is made of cast steel, and the material is ZG30MnSi.This is our factory’s common product, normal annual productivity is 300tons.

A brief introduction to casting technology:

(1) Investment casting (investment casting) Investment casting: usually refers to making a pattern in fusible materials, covering the surface of the pattern with several layers of refractory materials to form a shell, and then melting the pattern out of the shell to obtain no points. The casting of the molding surface can be filled with sand and poured after high-temperature roasting. Often referred to as "lost wax casting". Process flow: investment casting process features and advantages: 1. High dimensional accuracy and geometric accuracy; 2. High surface roughness; 3. Complicated castings can be cast, and the cast alloy is not restricted. Disadvantages: complex procedures and high cost. Application: suitable for the production of small parts with complex shapes, high precision requirements, or difficult-to-perform other processing, such as turbine engine blades.

(2) Die-casting: Die casting uses high pressure to press molten metal into a precision metal mold cavity at high speed. The molten metal is cooled and solidified under pressure to form a casting. Process flow: Process characteristics and advantages: 1. The metal liquid bears high pressure during die-casting, and the flow rate is fast. 2. Good product quality, stable size, and good interchangeability; 3. High production efficiency and many die-casting molds are used; 4. Suitable for large batches Production and economic benefits are good. Disadvantages: 1. Castings are prone to small pores and shrinkage porosity. 2. Die-casting parts have low plasticity and are not suitable for working under impact load and vibration; 3. When high-melting alloy die-casting, the mold life is low, which affects the expansion of die-casting production. Application: Die castings were first used in the automobile industry and instrument industry, and later gradually expanded to various industries, such as agricultural machinery, machine tool industry, electronics industry, defense industry, computers, medical equipment, clocks, cameras, and daily hardware, etc.

Our Regular Products