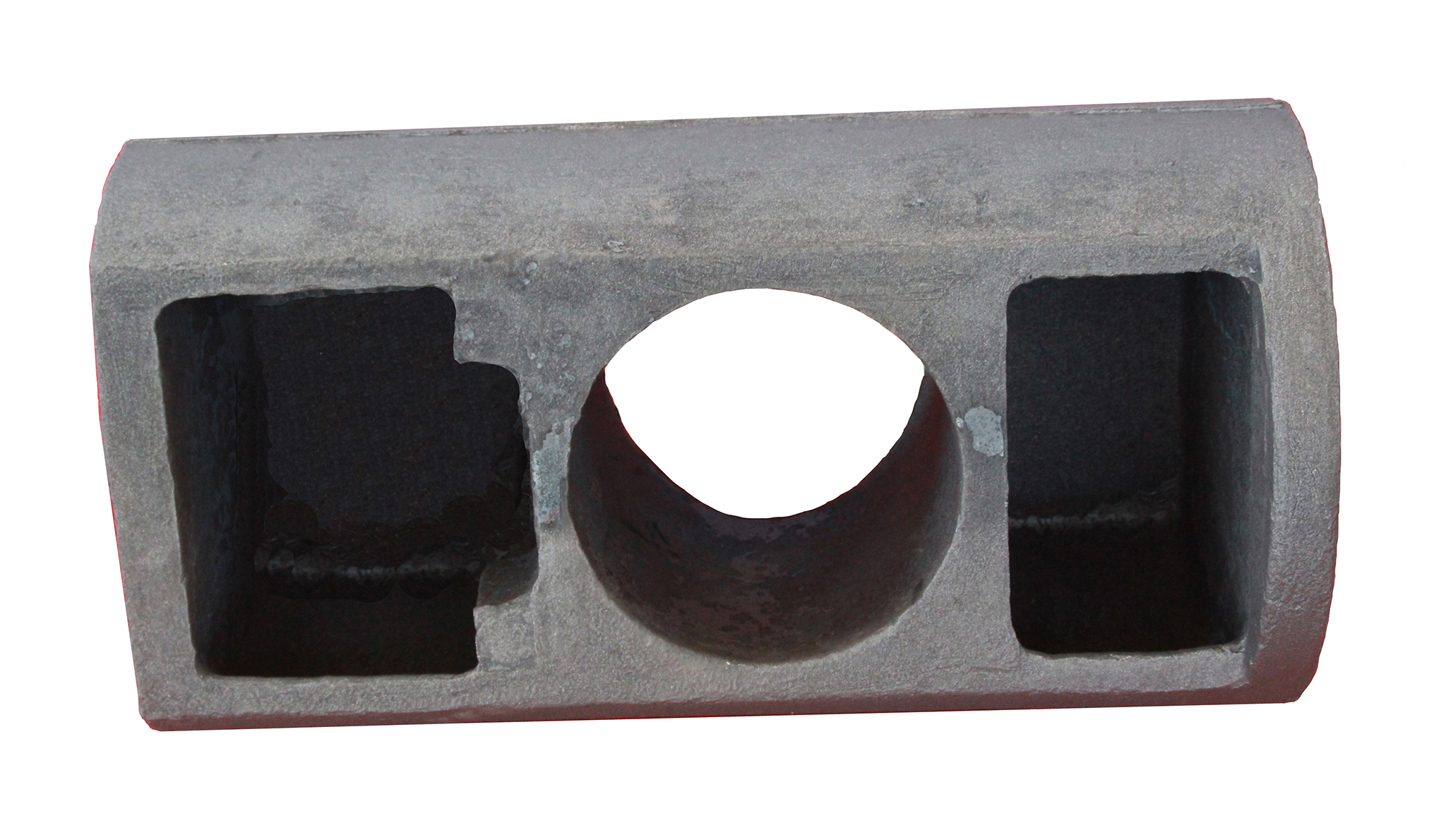

casting Cheebtsam rau thee plough, ua nyob rau hauv tshwj xeeb cam khwb cia hlau

Product Description

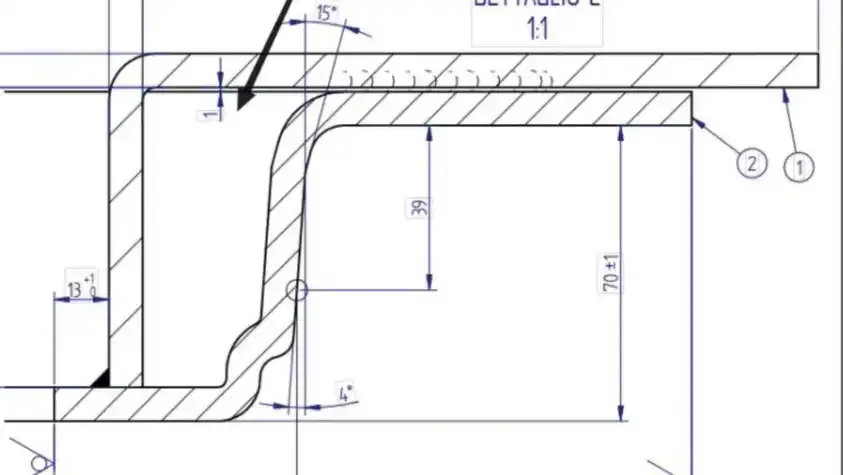

It is a part or accessory for a coal plow, it is made of cast steel, and the material is ZG30MnSi.This is our factory’s common product, normal annual productivity is 300tons.

Cov lus qhia luv luv rau kev siv tshuab casting:

(1) Kev nqis peev casting (kev nqis peev casting) Kev nqis peev casting: feem ntau yog hais txog kev ua cov qauv hauv cov ntaub ntawv fusible, npog cov txheej txheem ntawm ntau txheej ntawm cov ntaub ntawv refractory los ua lub plhaub, thiab tom qab ntawd yaj cov qauv tawm ntawm lub plhaub kom tau txais tsis muaj cov ntsiab lus. Lub casting ntawm molding nto tuaj yeem sau nrog xuab zeb thiab nchuav tom qab kub kub roasting. Feem ntau hu ua "poob ciab casting". Cov txheej txheem ntws: peev casting txheej txheem nta thiab qhov zoo: 1. High dimensional precision thiab geometric raug; 2. High deg roughness; 3. Cov txheej txheem nyuaj tuaj yeem nrum, thiab cov cam khwb cia hlau tsis txwv. Qhov tsis zoo: cov txheej txheem nyuaj thiab tus nqi siab. Daim ntawv thov: haum rau kev tsim cov khoom me me nrog cov duab nyuaj, siab precision yuav tsum, los yog nyuaj-rau-ua lwm yam, xws li turbine cav hniav.

(2) Tuag-casting: Tuag casting siv siab los nias molten hlau rau hauv precision hlau pwm kab noj hniav ntawm kev kub ceev. Cov hlau molten yog txias thiab solidified nyob rau hauv siab los tsim ib tug casting. Cov txheej txheem ntws: txheej txheem cov yam ntxwv thiab qhov zoo: 1. Cov hlau ua kua muaj kev kub siab thaum lub sij hawm tuag-casting, thiab tus nqi khiav ceev. 2. Cov khoom zoo, ruaj khov loj, thiab kev sib hloov zoo; 3. Kev ua haujlwm siab ntau lawm thiab ntau cov pwm tuag-casting yog siv; 4. Tsim nyog rau cov khoom loj Ntau lawm thiab kev lag luam muaj txiaj ntsig zoo. Disadvantages: 1. Castings yog yooj yim rau me me pores thiab shrinkage porosity. 2. Tuag-casting qhov chaw muaj cov yas tsis tshua muaj thiab tsis haum rau kev ua haujlwm hauv kev cuam tshuam thiab kev co; 3. Thaum high-melting alloy tuag-casting, pwm lub neej yog tsawg, uas cuam tshuam rau expansion ntawm tuag-casting ntau lawm. Daim ntawv thov: Tuag castings yog thawj zaug siv hauv kev lag luam tsheb thiab ntsuas kev lag luam, thiab tom qab ntawd maj mam nthuav dav mus rau ntau yam kev lag luam, xws li cov tshuab ua liaj ua teb, tshuab cuab yeej kev lag luam, kev lag luam hluav taws xob, kev lag luam tiv thaiv, khoos phis tawj, khoom siv kho mob, moos, koob yees duab, thiab khoom siv niaj hnub. , lwm.

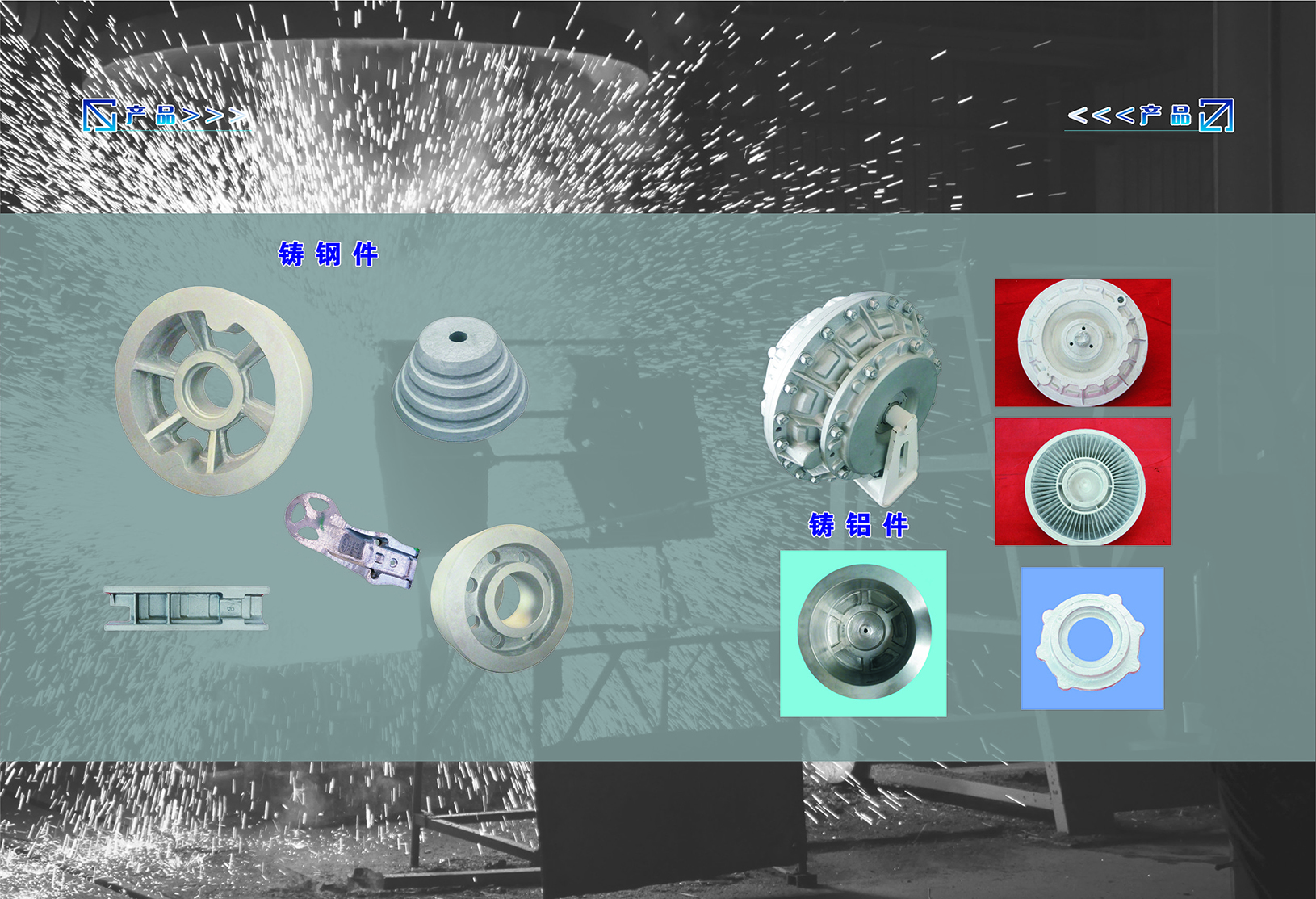

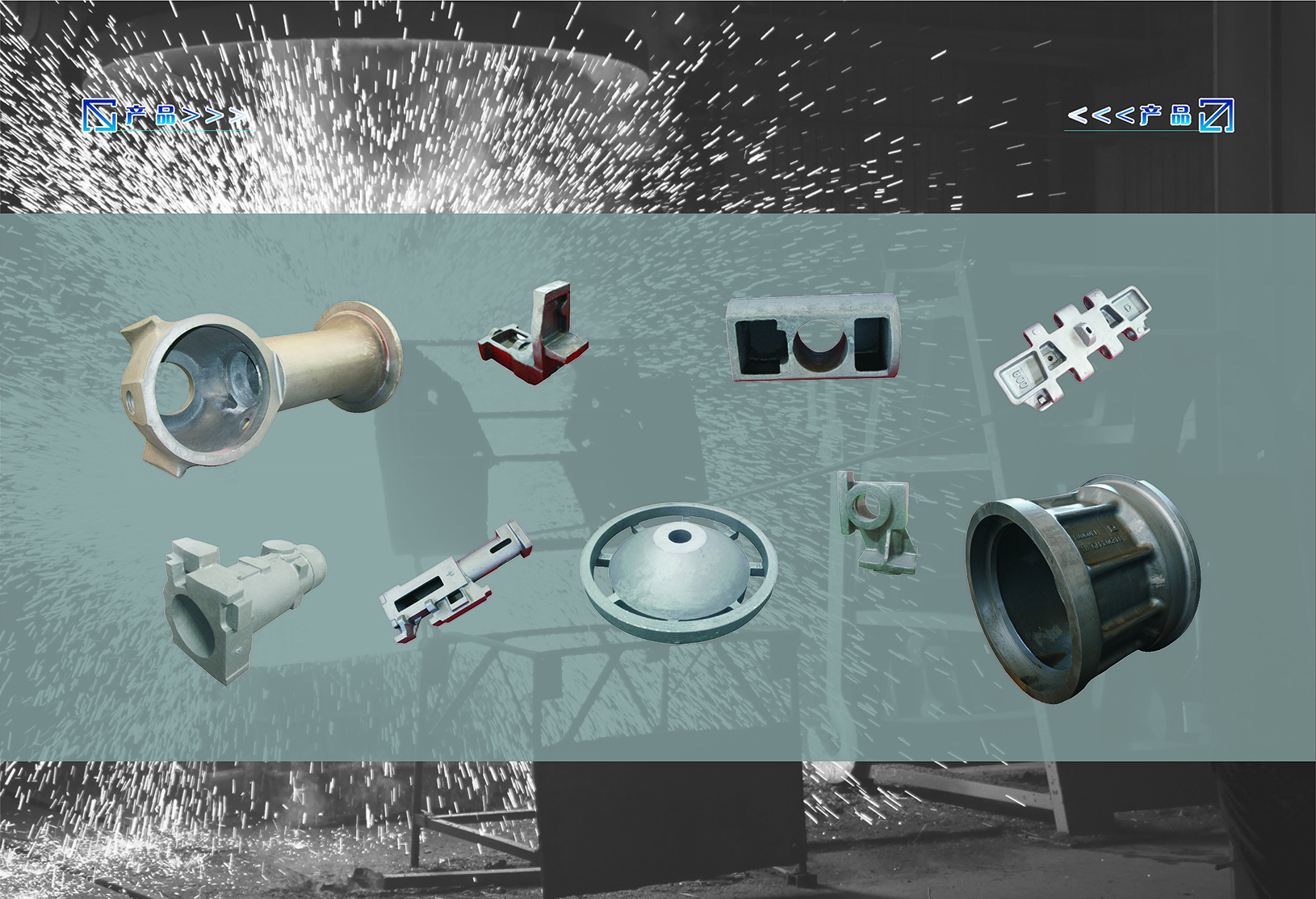

Peb cov khoom tsis tu ncua